Struggling with slow electronics production? Find a system that handles dispensing, cuts waste, saves space, and keeps every deposit precise.

Electronics manufacturers often face challenges with production speed, flexibility, and space constraints. Managing multiple dispensing processes typically requires several machines, increasing floor space, energy use, and maintenance. Consistently precise deposits of solder paste, glue, or thermal materials can also be hard to achieve, especially on complex boards.

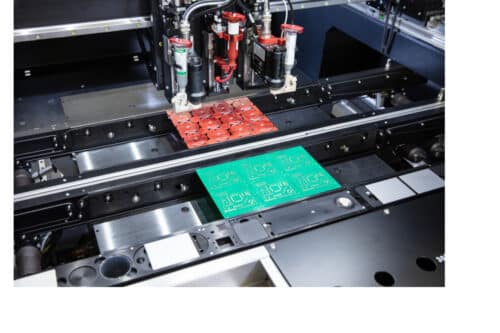

The Tarantula Dual Lane from Essemtec addresses these problems by combining multiple dispensing processes in a single platform. Its dual-lane design allows two independent lanes to operate at the same time, and it can handle up to three valve heads in parallel. This means solder paste, glue, epoxy, thermal paste, or dam and fill applications can all run on one system, reducing the number of machines needed and simplifying production lines.

High-speed, precise deposition is made possible with Essemtec’s next-generation control and motion technology. Jet-on-the-Fly allows up to 1.1 million dots per hour for standard boards and around 350,000 dots per hour for complex high-speed solder paste applications. For glue, it can reach 2 million dots per hour. Optional 2D SPI with automatic correction ensures consistent quality, while integrated traceability tracks materials and parameters throughout production.

The system jets only the material required, reducing waste and eliminating the need for stencil cleaning chemicals. Its versatility covers fine-pitch solder deposits, staking, microcoating, dielectric ink, liquid metal, shielding, edge bonding, and more, adapting precisely to production needs.

Set-up and operation are simplified with Essemtec’s ePlace software and Optimizer tool. Jobs can be prepared in minutes, and Gerber file import allows direct transition from design to production, automatically generating recipes for new projects. The platform is fully upgradable, supporting software updates, new valve technologies, and additional features to protect investment over time.

Manufacturers running high-volume SMT production can now leverage dual-lane productivity across dispensing and assembly, thanks to compatibility with the Puma Ultra Pick-and-Place platform. Integration with EasyLogix PCB-Investigator ensures smooth workflow from PCB design to production across the compaany’s adaptive equipment ecosystem.