From traction inverters to chargers, power electronics designers are turning to low loss silicon carbide dies to meet efficiency and reliability targets.

As global decarbonization accelerates, power electronics manufacturers face increasing pressure to reduce energy loss while managing higher power densities and long term reliability requirements. Applications such as electric vehicle traction inverters, onboard chargers, and renewable energy power supplies must deliver consistent performance while operating under demanding electrical and thermal conditions. This is driving growing demand for advanced power semiconductor bare dies that enable efficient system integration without compromising durability or quality.

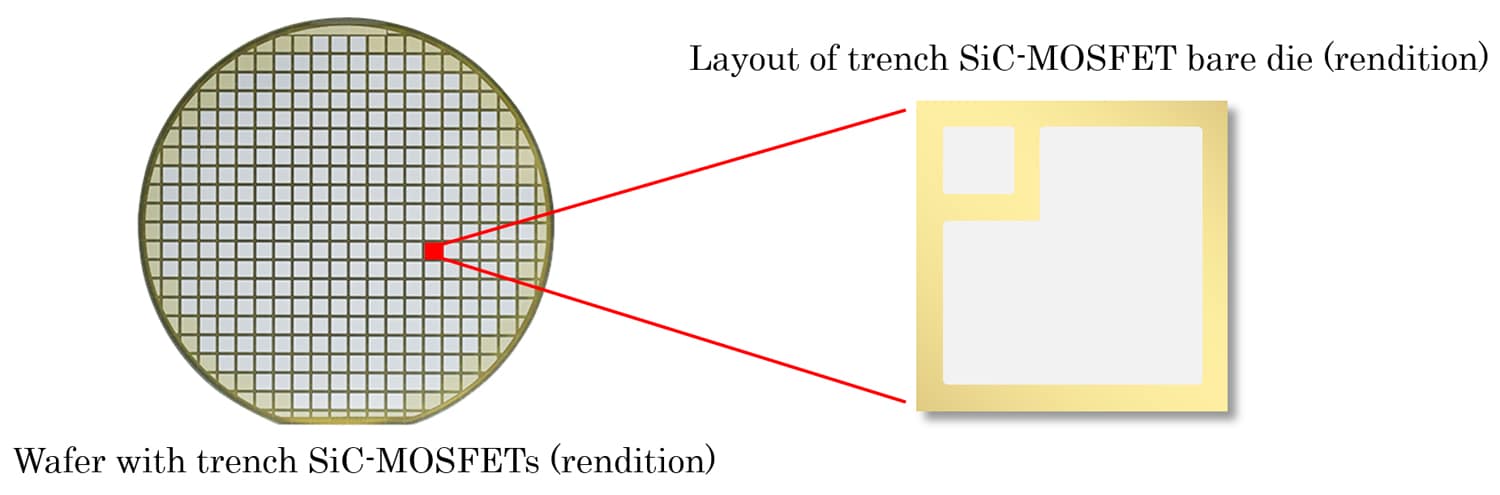

Mitsubishi Electric is addressing this need by announcing the samples of four trench silicon carbide MOSFET bare dies. Designed for use in EV powertrains, charging systems and renewable energy infrastructure, the new bare dies support lower power consumption while maintaining high performance. By offering bare die formats, the company enables greater flexibility for embedding semiconductors directly into next generation power electronics architectures.

The lineup include:

- WF0020P 0750AA: 750 V rated, 20 milliohm on resistance

- WF0040P 0750AA: 750 V rated, 40 milliohm on resistance

Targeted for high performance EV traction inverters

- WF0060P 0750AA: 750 V rated, 60 milliohm on resistance

- WF0080P 0750AA: 750 V rated, 80 milliohm on resistance

Optimized for onboard chargers for renewable energy power systems

The trench SiC MOSFET bare dies use the company’s proprietary trench structure, achieving approximately 50% lower power loss compared to conventional planar SiC MOSFETs. This supports higher efficiency and reduced heat generation. In addition, the company’s proprietary gate oxide film manufacturing process suppresses variation in resistance and power losses.

Key features of the MOSFET include:

- Trench SiC MOSFET bare die design for flexible system embedding

- Approximately 50% lower power loss than planar SiC MOSFETs

- Stable on resistance through proprietary gate oxide manufacturing

- Suitable for EV, charging and renewable energy applications

- Designed for long term performance and reliability

Building on more than a decade of experience supplying SiC power semiconductor modules for industrial equipment, air conditioning systems and railway inverters, the company is expanding its portfolio to meet growing demand for highly efficient embedded solutions.