Designed for high current applications, the components deliver increased power handling while maintaining precision across wide operating temperatures.

ROHM Unveils the UCR10C Series of Sintered Metal Shunt Resistors

Increasing current levels in automotive and industrial electronics are driving demand for compact shunt resistors that can handle higher power without compromising accuracy or long term reliability. Conventional thick film and metal plate designs face limits in power density, thermal stability, and junction durability under wide temperature swings.

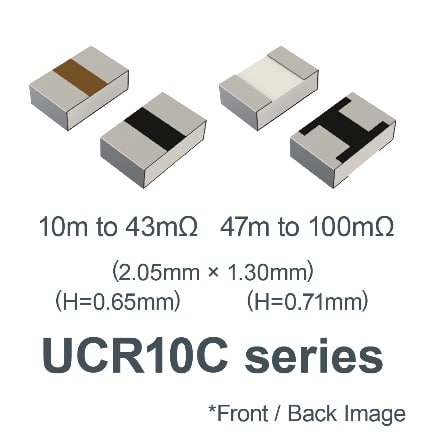

ROHM has launched the UCR10C Series, a sintered metal shunt resistor positioned as the highest rated power offering in the 2012 size category. The devices cover resistance values from 10 mΩ to 100 mΩ and target current sensing applications requiring higher power handling in space constrained designs.

The devices form a copper based resistive element on an alumina substrate using a sintering process. An optimized heat dissipation structure enables rated power levels of 1.0 W and 1.25 W, approximately double that of comparable same size thick film and metal plate resistors. The metal resistive element achieves a low temperature coefficient of resistance from 0 to +60 ppm per °C and maintains durability across temperature cycle testing from 55°C to 155°C over 1000 cycles.

Key features of the resistor include:

- 2012 size sintered metal shunt resistor

- Rated power up to 1.25 W

- Resistance range from 10 mΩ to 100 mΩ

- Low TCR of 0 to +60 ppm per °C

- Copper based resistive element on alumina substrate

- High reliability under extended temperature cycling

- Fully lead free construction

The development demonstrates higher power density current sensing in standard chip resistor footprints while maintaining precision and thermal reliability for demanding electronic systems.