New surface-mount optical sensors increase vertical headroom, enabling more flexible encoder and position-sensing designs across industrial and consumer electronics.

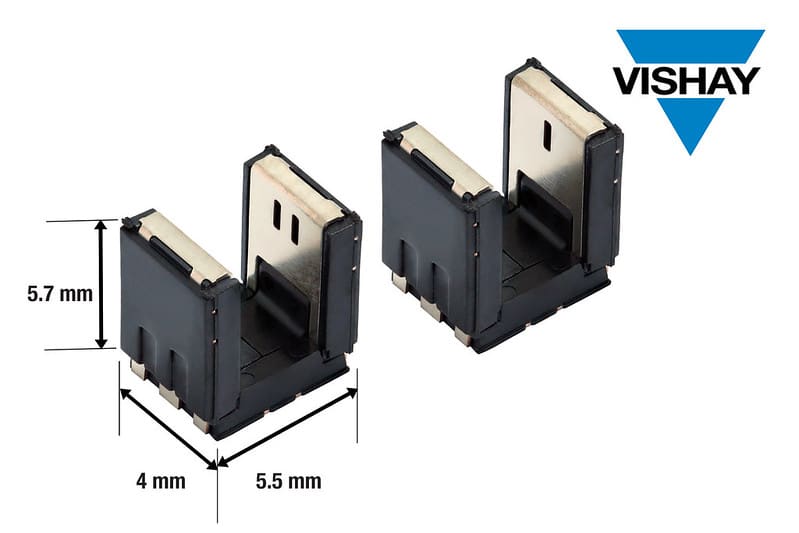

A new generation of surface-mount transmissive optical sensors by Vishay Intertechnology is entering the market, targeting applications where mechanical tolerance, compact footprints, and reliable motion detection are critical. Designed for industrial, consumer, and telecom systems, the devices introduce a significantly taller dome structure that expands vertical headroom without increasing the overall PCB footprint.

The key features are:

- 42% higher dome for increased vertical headroom

- Compact 5.5 mm × 4 mm SMD footprint

- Single- and dual-channel options, including direction sensing

- 950 nm IR operation with fast 14 µs / 21 µs response times

- MSL 1 rating, Pb-free reflow compatible, RoHS compliant

The sensors offer a 42% higher dome compared with earlier industrial-grade alternatives. This added height allows designers to accommodate larger code wheels and looser mechanical tolerances, particularly in turn-and-push interfaces, rotary encoders, and optical encoding assemblies. The result is greater freedom in mechanical layout while maintaining precise optical alignment.

Both single-channel and dual-channel variants are available, addressing a wide range of sensing requirements. In encoder and automation systems, the devices support accurate position, motion, and speed detection. The dual-channel option additionally enables direction sensing, making it suitable for more advanced control interfaces in industrial drives, tools, and automation equipment. Beyond factory environments, the sensors also target consumer electronics such as appliances, entertainment systems, health and care devices, as well as switches, relays, antennas, and mobile broadband routers.

Technically, the sensors integrate an infrared emitter with face-to-face phototransistor detectors in a transmissive configuration. They operate at a wavelength of 950 nm and deliver a typical output current of 1.5 mA. A 3 mm gap width and narrow 0.3 mm apertures support precise optical interruption, while fast rise and fall times—14 µs and 21 µs—enable reliable detection of rapid motion.

From a manufacturing standpoint, the devices are qualified for high-volume assembly. An MSL 1 rating provides unlimited floor life, and compatibility with lead-free reflow soldering simplifies integration into standard production lines. The components are also halogen-free, RoHS-compliant, and aligned with green manufacturing requirements.With samples and production quantities now available, these transmissive sensors aim to give designers more mechanical flexibility without compromising optical performance or manufacturability.