A new surface-mount CO₂ sensor shrinks footprint by 75%, enabling dense, low-power integration for demand-controlled ventilation in zero-energy buildings.

A newly introduced CO₂ sensing device unveiled by Senseair is set to ease one of the biggest bottlenecks in demand-controlled ventilation (DCV): space. The latest generation sensor reduces volume by around 75% compared with earlier designs while retaining measurement accuracy and ultra-low power operation. Crucially for electronics designers, it can be mounted directly onto PCBs using standard surface-mount reflow processes, opening the door to tighter, cleaner HVAC and indoor air quality (IAQ) designs.

The key features are:

- 75% smaller volume than previous designs

- Surface-mount, reflow-solderable PCB integration

- NDIR-based CO₂ measurement technology

- 400–10,000 ppm range with high accuracy

- Ultra-low power operation for battery devices

The launch comes as building regulations worldwide, especially in Europe, push aggressively toward zero-emission construction. Under updated energy-performance rules, new buildings will need to minimise energy use and rely more heavily on renewable sources. DCV systems, which regulate airflow based on measured CO₂ levels rather than temperature alone, are gaining traction because they reduce energy consumption while maintaining occupant comfort. However, widespread deployment has been constrained by the size and installation complexity of conventional CO₂ sensors.

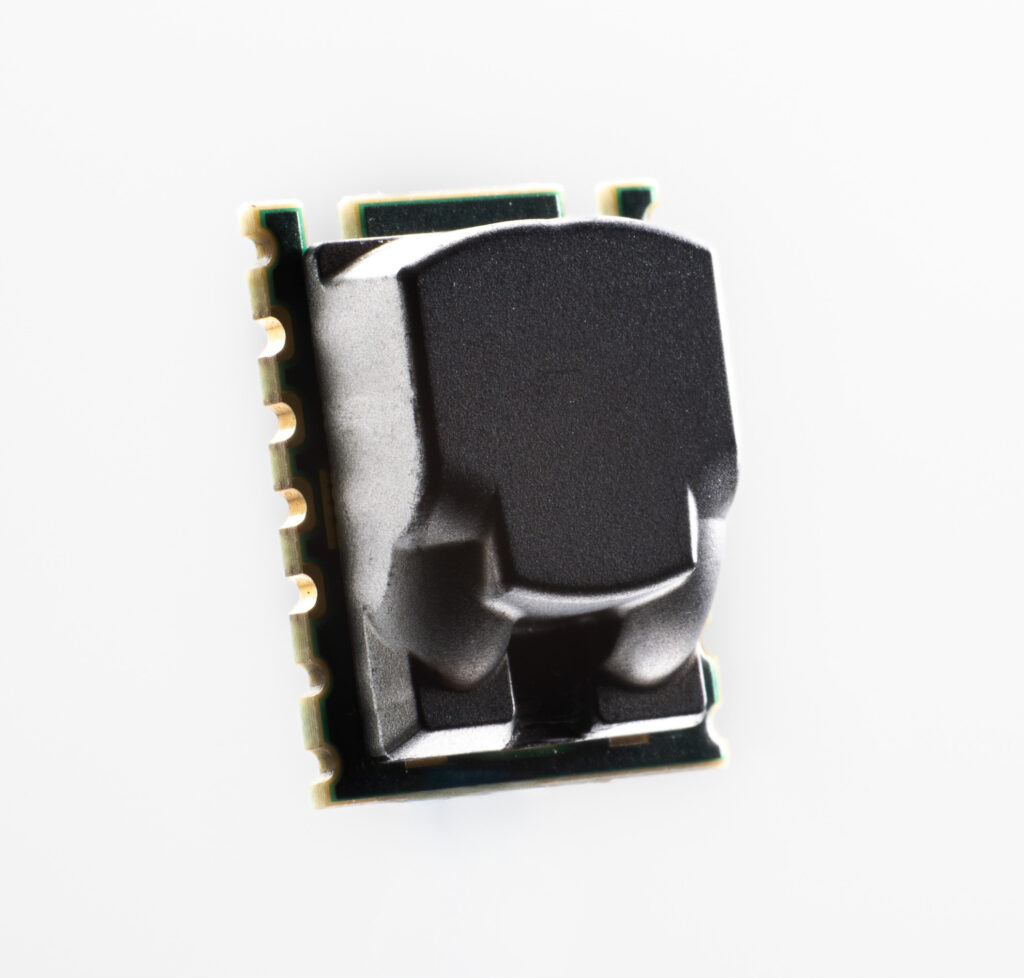

The new device addresses these constraints through a redesigned structure based on non-dispersive infrared (NDIR) absorption technology. Despite its compact footprint just 18 mm × 15 mm × 7 mmit delivers a measurement range from 400 to 10,000 ppm with accuracy comparable to larger, established sensors. This allows designers to integrate CO₂ sensing into wall-mounted monitors, air-conditioning equipment, and compact IAQ modules without compromising aesthetics or layout flexibility.

Low power consumption remains a key differentiator, particularly for retrofit projects where running new cables is impractical. The sensor’s efficiency supports battery-powered operation, enabling flexible placement across offices, commercial buildings, and residential environments. As a result, it fits well into building energy management systems (BEMS) that require distributed sensing at scale.

The sensor is intended for global deployment across Europe, North America, and Asia, and is designed to meet widely adopted building and indoor air quality standards. With sampling underway and volume production planned within the year, the device is positioned to accelerate adoption of DCV in both new construction and retrofits.