New method lets circuits snug irregular 3D surfaces

Chinese researchers have developed a novel electronics fabrication technique that could redefine how high-performance circuits are integrated onto curved and irregular surfaces from wearable tech to aircraft components, overcoming a long-standing limitation of traditional rigid boards.

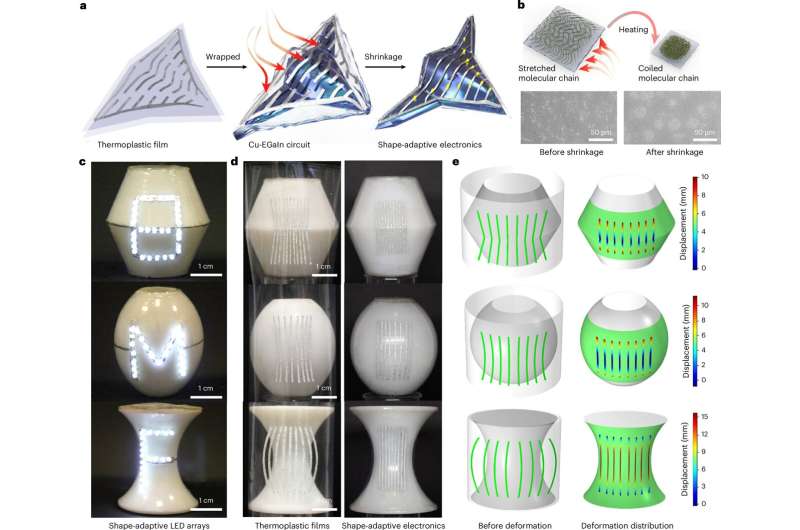

At the heart of the innovation is a heat-shrink approach that combines printable circuits with a shrinkable thermoplastic film. Standard circuits are first printed flat onto a common thermoplastic that contracts when heated. Instead of brittle copper traces that would crack during shrinkage, the team uses semi-liquid metal conductorsa gallium-indium-copper blend that stays put during printing but remains fluid enough to flex without breaking electrical continuity.

The researchers used computer simulations to map how the film deforms on different shapes so that designs can be pre-optimized for specific curved surfaces. Once prepared, the film is heated with warm air or even 70 °C water to conform tightly to the target object’s geometry without damaging it.

In testing, circuits fabricated this way showed high resilience, retaining electrical performance after thousands of bending and twisting cycles, a clear improvement over conventional wires and traces, which tend to fracture under similar stress.

The team published their findings in Nature Electronics, signaling a significant step forward in shape-adaptive electronics. Beyond the lab, the method has been demonstrated on a variety of real-world objects. Researchers successfully applied sensors to fresh fruit to monitor temperature and humidity, mounted circuits to model aircraft wings for built-in heating systems (useful for de-icing), and even created smart bandages capable of monitoring their own condition.

These early examples underscore the technology’s versatility and potential for broad impact in sectors like aerospace, healthcare wearables, robotics, and logistics wherever electronics must conform to complex, non-planar surfaces.

While further refinements are still underway, experts see this shrink-to-fit process as a promising route toward durable, high-performance electronics that truly wrap the real world from curved skins to flexible sensors without the manufacturing complexities that have hindered previous flexible circuits.