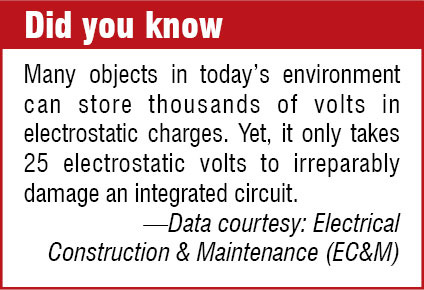

The most serious danger when working with electronic components is posed by electrostatic discharge (ESD). Sudden discharge of static electricity, or ESD, is very common. Everyday materials (such as glass, ceramic and plastic) are inherently charge-generating, and with miniaturisation of today’s complex devices, technology has multiplied the number of circuits and decreased their size, thereby increasing the risk of damage by ESD.

While the human body might not be susceptible to harm from this inevitable natural phenomenon, it is highly probable for electronic circuitry and components to be affected by ESD catastrophically or latently. In the latter case, although the electronic device could appear to work just fine, it could fail to function sometime in the future.

In this article, we focus on solutions that could help you control ESD and create a static-safe work area.

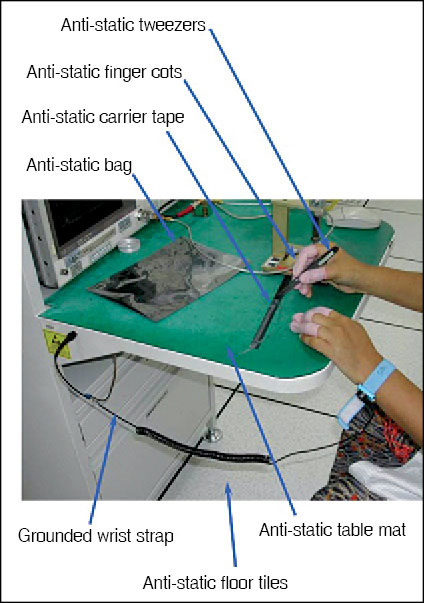

Those who wish to counter this problem must take various aspects into account, such as ESD-safe workstations where electrostatic discharge is safely channelled to earth, electrostatically discharging shoes, work-wear and ESD armbands with spiral cable that discharges voltage softly and safely via a large resistance (approximately one megaohm) from the operator to earth.

Tools for ESD detection and control

ESD materials are generally subdivided into three main categories: anti-static (109 ohms to 1012 ohms), dissipative (105 ohms to 109 ohms) and conductive (103 ohms to 105 ohms). ESD tools are equipped with electro-statically discharging (dissipative) handles that have a defined surface resistance of about 106-109 ohms. That guarantees soft discharging within a set period of time and in a controlled and safe manner, so that sensitive components cannot be damaged. Most ESD-safe hand tools with static dissipative handles are made of carbon steel or stainless steel.

IEC61340-5-1 standard specifies technical requirements for the design, use and control of a protected area so that electrostatic-sensitive devices, having sensitivity of 100V (human body model test) or higher, can be handled with minimal risk of damage from procurement to end of their life.

There are diverse kinds of tools and systems available for detection, restriction and protection from ESD. Electronic facilities require ESD protection during inspection, storage and warehouse, assembly, research and development (R&D), packaging, test and inspection and field service repair. Dedicated manufacturers adopt various anti-static safety measures while designing their products.

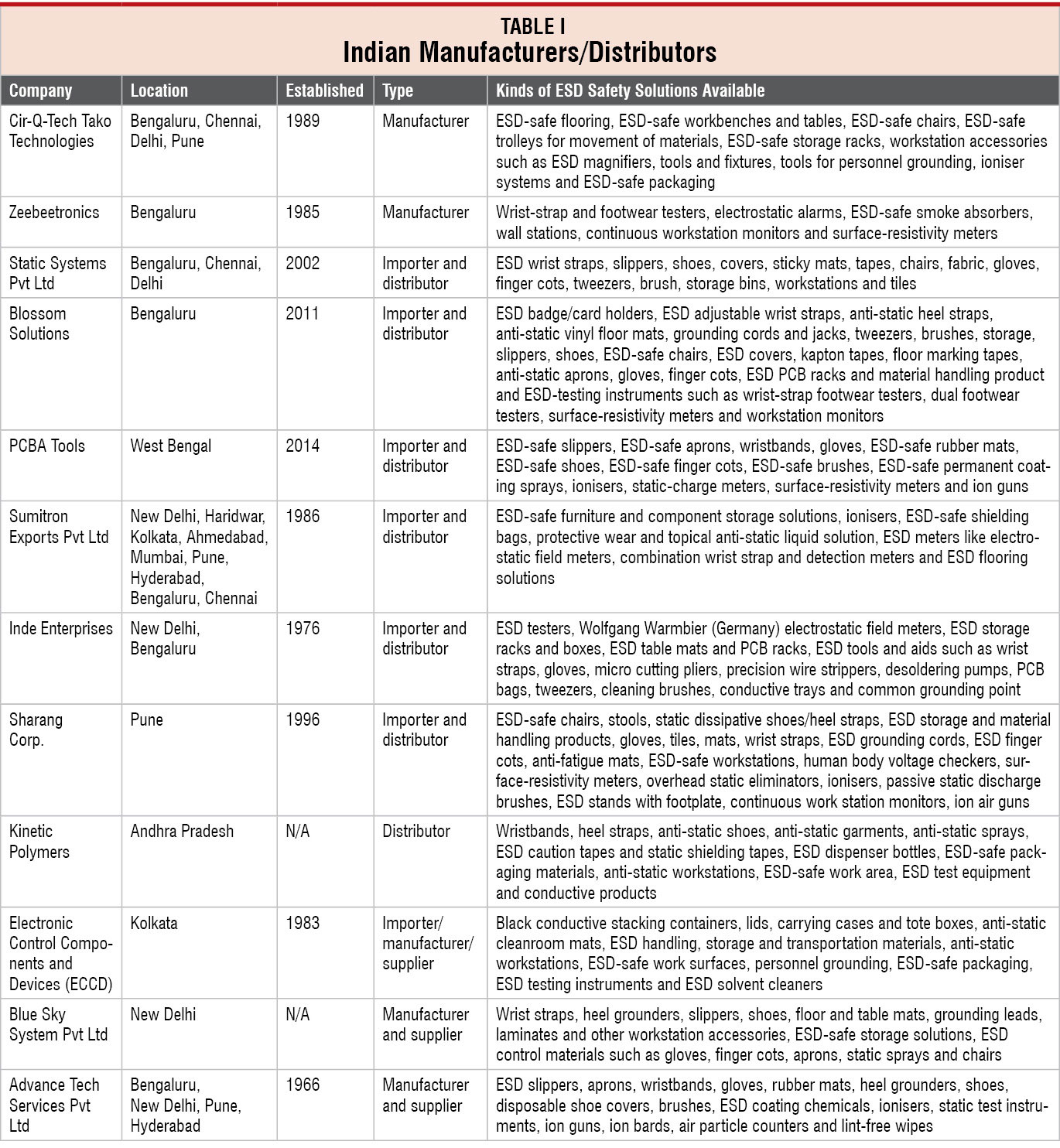

Correct education coupled with the right set of tools can protect against the many dangerous effects of ESD. Let us take a look at some of the necessary equipment required to create ESD-safe products. Manufacturers and distributors of various ESD control products in India are featured in Table I and Table II has a list of various ESD products, their brand names and pricing.

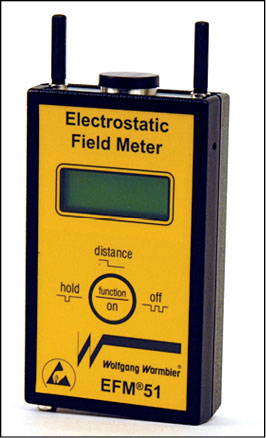

Electrostatic field meters. The most commonly used equipment for detecting static charges in today’s manufacturing environment is an electrostatic field meter, or ESD meter. It is very effective in detecting the presence and magnitude of static charges. The latest meters in the market are mostly digital, battery-operated, handheld and come with a rotating chopper. ESD meters help in detecting and accurately measuring electrostatic fields, potential and discharge times.

Surface-resistivity meters. These meters are employed for making point-to-point resistance and resistance-to-ground measurements including resistance of persons, ESD shoes, flooring or any kind of ESD protective material. Surface-resistivity meters usually record measurements in accordance with such standards as Electrical Over-Stress (EOS)/ESD Association Standards S-4.1, IEC 61340-4-1 Ed. 2.0 and IEC 61340-2-3, to name a few.

To make the measurement process hassle-free, some meters come equipped with integrated data loggers (with limited storage capability) and communication ports for wirelessly transmitting data. With the help of two internal probes of electrodes, the typical range for measurements is between 103 ohms and 1012 ohms.

Surface resistivity plays a key role in monitoring and examining the resistive characteristics of packaging materials, work bench surfaces, floor mats, storage bags and other items used in the electronics assembly and packaging industry.

Handheld and work-holding tools. Brushes as an anti-static tool enable manufacturers of electronic and static-charge-sensitive products to clean and make products that do not create static charges. Some vendors also provide custom-made clean room/ESD brushes.

Cutters with dissipative, soft-grip handles and induction-hardened cutting edges are used for superior performance. Pliers are used for gripping, holding and bending, and any electrostatic energy present is discharged through the handles in a gradual and controlled manner, which protects components endangered by electrostatic discharge. Ergonomically-designed cutters and pliers with a good hand grip are especially important for professional technicians for lead cutting.

Cutters with dissipative, soft-grip handles and induction-hardened cutting edges are used for superior performance. Pliers are used for gripping, holding and bending, and any electrostatic energy present is discharged through the handles in a gradual and controlled manner, which protects components endangered by electrostatic discharge. Ergonomically-designed cutters and pliers with a good hand grip are especially important for professional technicians for lead cutting.

Another work-holding tool, a tweezer, is used for holding, pulling, squeezing, picking up components and plucking jobs. The protective coating on these prevents harm to sensitive electronics from ESD.

Magnifying lamps provide full protection against ESD. The complete lamp (head, lens, joint and arm) is grounded and has special static-dissipative materials to smoothly take away static charges in a controlled manner, preventing any build up of static electricity, which gives complete protection against ESD.

Ionisers. In order to reduce potential damage that could be caused by ESD, ionisers are another extensively used equipment. Ionisers are most commonly used by manufacturers of electronic and surface-mount devices (SMDs) as well as printed circuit board (PCB) industries.

Sometimes, static-control products such as ESD flooring, mats and wrist straps are unable to completely eliminate static charges. An ioniser removes static charges from surfaces, thereby providing additional protection. Depending on the application usage and industry, new-age ionisers are available in benchtop, gun, nozzle, bar and overhead box form factors.

Anti-static wristbands. ESD wrist straps or wristbands allow the personnel doing assembly, maintenance or repair work to work without being concerned about static electricity. Fitted around the wrist, as the name suggests, these are usually fully-adjustable and dissipate potential harmful charges to the ground, thereby allowing personnel to handle ESD-sensitive devices safely.

Today’s wrist straps are available with and without cords. Wired wrist straps are usually about 1.5m to 2.4m (5-feet to 8-feet) long, come with a standard alligator clip for ground termination and are the most-preferred over wireless wristbands for their reliability.

Other tools

ESD work-surface mat rolls, ESD floor-mat rolls, ESD cushion bags and boxes, ESD sheet protectors, ESD finger cots, ESD gloves, ESD jackets, ESD lables, ESD tapes and anti-static tweezers are some other items to consider depending on your application usage. There are a variety of anti-static bags available for storage and transportation of sensitive devices and components such as multilayer static shielding metallised bags, black conductive bags (usually seen with hard disks), pink bubble bags (seen in development boards packaging), foam covers and boxes.

Finger cots are available in different variants such as general-purpose finger cots, industrial-grade finger cots, nitrile finger cots, conductive finger cots and black or static dissipative finger cots. These are usually powder-free, made of latex material and are perfect for electronic assembly and manufacturing. Table mats used on work surfaces need to be grounded securely. Static-control test stations are also available to determine if ESD wrist straps or shoes are functioning properly.

In some situations, wearing wrist straps might not be viable. In such cases, use of ESD shoes or heel straps is recommended. In anti-static shoes, the grounding cord usually runs into the socks to make contact with the skin. ESD footwear are only effective with anti-static floor tiles. Even basic equipment such as chairs, table, stools, cabinets, brushes and storage bins are available to create complete and secure anti-static workstations in facilities. In cases where air guns are required, one must make sure the guns do not generate static charges in the air stream. Special guns are available for this purpose.

Good-quality gloves provide anti-static protection up to 108 ohms and are nylon or polyester knit with conductive carbon fibres. ESD mats are available in single- and dual-layer forms. For general purpose, single-layer mats are preferred as these are cost-effective. ESD vinyl mats are ideal for static dissipative and flexible work surfaces. ESD tweezers are very handy and great to have if you are working with surface-mount or compact components.

Keep your devices and components safe

ESD can be a serious cause of malfunctions and crashes in today’s sophisticated as well as simple electronic components and systems. With the best anti-static precautions, you can make sure your devices and components are ESD-protected, particularly when these are disassembled.

Warranty is an important factor to consider while buying ESD tools. Manufacturers typically offer 12 to 24 months of warranty for products such as ionisers, surface-resistivity meters, hot-air guns and wrist-strap testers.

Abhishek A. Mutha is a senior technical correspondent at EFY. This article was written with inputs from Biswajit Das, manager – R&D, EFY Labs