High power LED lighting is harder than it looks. Power, dimming, control, and communication collide in one design. See how these problems can be solved.

Design engineers developing LED lighting systems for outdoor, industrial, and entertainment use face challenges. LEDs require power conversion to reduce losses and thermal stress. Maintaining stable output while supporting dimming across multiple LED strings adds complexity. Many installations require networked and remotely controllable lighting, which adds the need to integrate communication protocols with power electronics. Engineers must also account for AC input compatibility, regulatory compliance, system reliability, and operating lifetime. Without a reference platform, these requirements increase design time and risk.

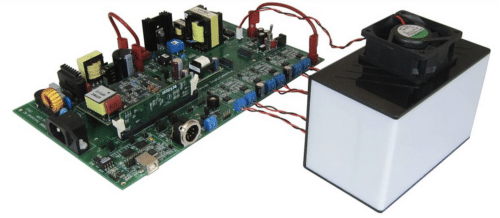

TIDM-AC-LED-COM, a reference design from Texas Instruments (TI), addresses these issues by combining LED driving, power conversion, and communication support in one system. It provides a 250 W AC-input LED driver with a six-string LED lamp for demonstration. The driver operates at over 90% efficiency with a power factor of 0.99, helping engineers meet efficiency targets while delivering consistent LED output. Support for lighting communication protocols enables networked operation and remote control without additional communication hardware.

The power stage supports AC input and LED loads up to 250 W, allowing use across markets and lighting applications. The architecture integrates AC rectification, single-phase boost power factor correction, and a half-bridge LLC resonant DC/DC converter. Separate dimming stages for each LED string allow brightness control. A load-reactive control method enables dimming while maintaining efficiency.

Each LED string connects through a MOSFET to allow independent dimming. The on-time of each MOSFET controls the average LED current. Since LED brightness is proportional to current, pulse-width modulation is used to set brightness levels. This gives control over multi-string LED systems without reducing efficiency.

The power factor correction stage uses a controller, while a digital controller manages the LLC stage, LED string control, communications, and system supervision. Available processing bandwidth allows the same controller to support lighting network protocols and monitoring functions along with power control.

To reduce development effort, the design is available as a developer platform. It includes hardware, software examples, libraries, a graphical user interface, application notes, and guides. This allows engineers to evaluate system behavior, test dimming methods, and explore communication features without building the full system.

The system accepts AC input, which passes through a power factor correction stage to improve efficiency and meet regulatory requirements such as harmonic current limits. The corrected DC output feeds an LLC resonant DC/DC stage that provides isolation and generates the required voltage for the LED strings. For applications with high LED counts or light output, the switched-mode power supply architecture supports efficiency and thermal control.

Communication support enables lighting systems where multiple luminaires are managed from a controller or application. Standards support this using twisted-pair wiring, wireless links, or power line communication, allowing integration into connected environments without managing each fixture separately.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.