Combining edge AI, multi-sensor perception, and real-time connectivity in a ready-to-deploy framework, the platform streamlines prototyping, reduces integration complexity, and speeds up time to market for industrial and service robotics innovations.

For design engineers working to bring next-generation autonomous machines to market, having a robust reference design is indispensable. The new reference platform built around the Qualcomm Robotics RB5 architecture empowers product teams to accelerate development, minimise integration risk and pivot quickly from concept to prototype. By offering a proven baseline — one that combines edge-AI, multi-sensor perception and connectivity in a production-ready form-factor — this design supports engineers in hitting performance benchmarks without reinventing the foundational hardware and system architecture.

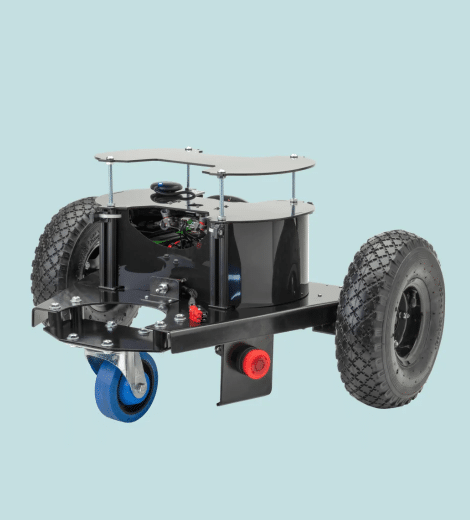

The “RB5 AMR Reference Design” from ModalAI leverages the Qualcomm QRB5165 processor alongside a comprehensive sensor and connectivity suite to enable autonomous mobile robot (AMR) deployments. On the computing front, the platform brings together an octa-core Kryo CPU (up to 2.84 GHz), Adreno GPU and Hexagon Tensor Accelerator supporting deep-learning workloads at up to 15 TOPS. For perception, the system features front and rear stereo cameras, a tracking image sensor, high-resolution 4K imaging, near-360° ultrasonic coverage and indoor GPS-denied navigation capability. Connectivity is addressed via multi-mode support including WiFi, 4G/LTE and 5G add-ons, enabling real-time data flow and scalable fleet coordination.

From a systems design perspective, this reference design dramatically reduces the time spent on baseline architecture from scratch. Engineers can adopt a validated platform with underlying hardware, sensor integration and software support already in place — focusing their efforts instead on value-added differentiation like application-specific algorithms, mechanical design and system packaging. The platform’s support for ROS 2 and Linux-based environments ensures familiarity and ecosystem synergies.

In practical terms, the specification breadth is impressive: support for multiple concurrent cameras, advanced vision pipeline with dedicated EVA (Engine for Video Analytics) hardware, and an industrial grade temperature range operative in demanding environments. For industries — logistics, warehousing, retail, agriculture, construction and utilities — this reference design offers a pathway to deploy smart mobile robots with industrial-grade autonomy and connectivity. Analyst commentary underscores how the RB5 AMR design combines AI and 5G to unlock new use cases for OEMs and robotics manufacturers.

This reference bundle delivers a compelling foundation for electronics and robotics engineers: high-performance compute, advanced sensor integration, edge-AI processing and connected communications — all neatly packaged into a ready-to-use architecture. By reducing development time, simplifying system integration and leveraging a strong hardware-software ecosystem, it positions teams to deliver smarter autonomous machines faster and more reliably.