Guides engineers through the hardware and firmware architecture of an induction cooker, addressing power electronics, control, safety, and EMI challenges to enable faster and more reliable appliance development.

NXP’s application note AN5030 serves as a practical reference design guide for induction cooker systems, offering design engineers a ready framework to develop cost-effective, safe, and energy-efficient home appliance solutions. Induction cooking is widely adopted in domestic kitchens, portable cooktops, built-in hobs, and smart appliances due to its fast heating, high efficiency, and precise control. However, designing such systems involves challenges related to high-voltage power electronics, EMI management, safety protection, and real-time control. AN5030 addresses these challenges by combining hardware schematics, control strategies, and firmware flow, making it especially valuable for engineers working on consumer appliances and power-electronics-based embedded designs.

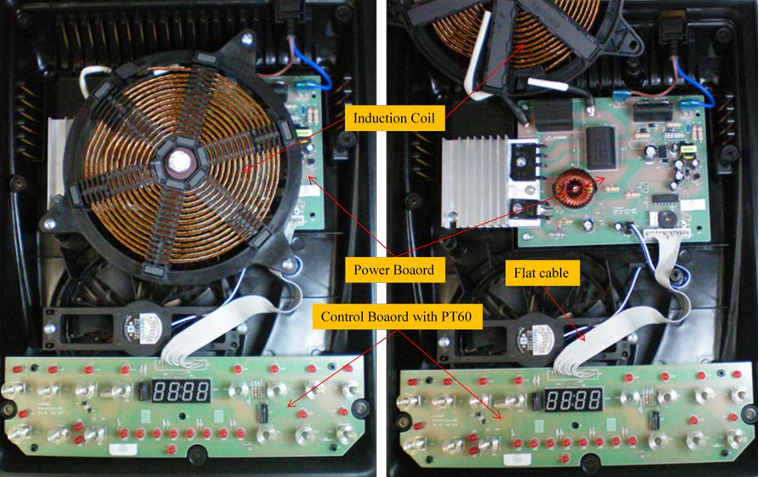

The reference design is centered on the S08PT family of 8-bit MCUs, which integrates peripherals optimized for appliance control. The overall system architecture is divided into a power board and a control board, simplifying development and validation. The power board processes the AC mains input, rectifying it to a high-voltage DC bus of around 310 V, and generates auxiliary rails such as +18 V and +5 V for gate drivers and logic circuitry. A resonant LC network connected to the induction coil forms the heating stage, transferring energy efficiently to compatible cookware through electromagnetic induction.

The control board, built around the S08PT MCU, manages all intelligence and safety functions. It handles PWM control of the IGBT, user interface management, sensor data acquisition, and fault monitoring. Built-in peripherals such as ADC channels, timers, comparators, and touch sensing inputs allow designers to reduce external components while still meeting real-time performance needs. Capacitive touch keys, LED or segment displays, and buzzer outputs can be directly managed by the MCU, enabling sleek and modern appliance interfaces.

AN5030 highlights several critical hardware design practices relevant to engineers. These include proper signal conditioning and filtering for voltage, current, and temperature sensing to ensure reliable ADC measurements in noisy environments. The note also stresses careful routing and RC filtering for display and touch interfaces to improve EMC robustness. Dedicated noise-detection circuits are described to prevent unsafe operation during mains disturbances, a key requirement for compliance with appliance safety standards.

From a firmware perspective, the reference design outlines a structured approach to system initialization, task scheduling, and power-control logic. Safety checks such as cookware detection, over-current, over-voltage, and over-temperature protection are executed before enabling power delivery. PWM duty cycle is ramped gradually based on real-time feedback, ensuring efficient heating while protecting the IGBT and resonant components from stress.

Overall, AN5030 functions as a complete, application-ready reference design that helps design engineers shorten development cycles, reduce risk, and build reliable induction cooker products. Its concepts are also applicable to other resonant power-control appliances, making it a useful resource beyond induction cooking alone.For more information, click here.