Hydrogen-powered vehicles are more efficient than a combustion engine as no greenhouse gases are emitted. However, the process of generating hydrogen should also be green. Commonly used processes for separating hydrogen from other substances include steam reforming of methane, gasification, and electrolysis.

Hydrogen has been used as a source of clean energy throughout history, from spacecraft and submarines to refineries and forklifts. When vehicles are powered by hydrogen fuel cells, the only by-product is water, which is emitted in the form of pure water vapour, and hence no greenhouse gases are emitted. In addition to hydrogen’s abundance in nature (as part of water and atmospheric gas), hydrogen-powered vehicles are more efficient than a combustion engine since there are no moving parts.

For zero net emissions, the process of generating hydrogen should also be green. Commonly used processes for separating hydrogen from other substances include steam reforming of methane, gasification, and electrolysis. Hydrogen is also a byproduct of many industrial processes where it is often treated as waste.

In the most popular process known as electrolysis, an electric current is passed through water to separate its primary constituents—hydrogen and oxygen. Electricity is not generated from fossil fuels but produced from sources like wind, solar, and hydro energies to mitigate carbon footprints.

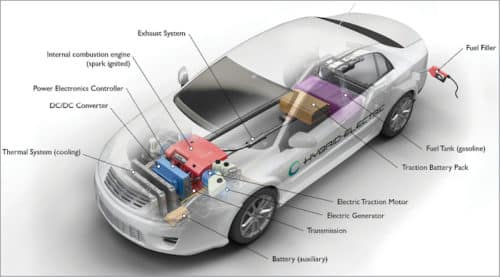

Hydrogen binds to most other substances and is a flammable gas. So, it is stored in liquid form in a fuel tank for ease of transportation until it is needed by the fuel cell stack (collection of electrodes). The amount of energy stored is decided by the size of the hydrogen fuel tank. Besides, in gaseous form, costs for compression, cooling, transport, and storage of hydrogen differ. Other key components of a hydrogen vehicle include electric traction motor(s), thermal system, auxiliary battery, traction battery pack, among others.

Manufacturers define the power of the vehicle by the size of the electric motor. Since the hydrogen engines are powered by an electric motor, these vehicles are also known as fuel cell electric vehicles (FCEVs). Power is generated when hydrogen inside fuel cells in vehicles undergoes reverse electrolysis. In this process, hydrogen present in tanks reacts with oxygen in the air to produce electrical energy, water, and heat. The electricity thus produced can either directly flow to the electric motor, which in turn is converted to mechanical energy to drive the vehicle’s wheels, or the energy can be stored in the battery pack, depending on the requirement. The auxiliary battery is mainly present to start the vehicle, and the thermal system keeps the operating temperature range in check.

Unlike battery electric vehicles (BEVs) that require recharging from an external source, FCEVs produce electricity themselves and use a small and lightweight battery for storage. The main benefits of this propulsion technology include no engine noise, quick charging time of less than five minutes, and longer range as compared to fully electric vehicles, regardless of environmental conditions.

In the Asian market, companies like Hyundai and Toyota have taken an interest in the field. Even worldwide, manufacturers like Audi and BMW are already working on hydrogen vehicles. Numerous experts are expecting a lot from this alternative, while others still remain skeptical.

Hydrogen-powered vehicles require high-pressure compression to work, which is difficult to achieve due to the low density of hydrogen. Also, there are a limited number of refueling stations that exist in just a few countries (like Germany and the US) due to lack of sufficient manufacturing and demand. The low demand for hydrogen vehicles stems from the fact that these are quite expensive to buy as well as use. The overall efficiency is almost half of what BEV has due to losses in hydrogen production through electrolysis.

New techniques can help in alleviating risks regarding the safety of such a vehicle. For instance, researchers at Northwestern University in the US, in collaboration with the Colorado School of Mines and National Institute for Standards and Technology, have recently come up with novel adsorbent materials that are built from organic molecules and metal ions or clusters and can store hydrogen at much lower pressures.

It is also crucial to develop advanced infrastructure to refuel these vehicles and shorten transportation distances and make policies to increase their adoption. In the US, the California Energy Commission (CEC) and the state’s Air Resources Board provide subsidies for new hydrogen car buyers. South Korea plans to expand the country’s hydrogen refuelling infrastructure to 660 pumps by 2030. Completely switching to such clean energies will go a long way in keeping the air clean and ensuring sustainable mobility.