New motor driver ICs focus on ultra-low standby power, flexible H-bridge configurations, and reduced external components to support compact consumer and industrial motor control applications.

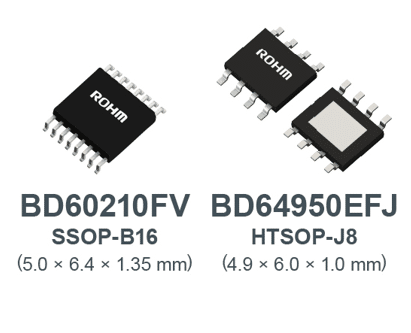

A new generation of brushed DC motor driver ICs from ROHM Semiconductor, aiming to simplify motor control designs while significantly cutting standby power consumption. Designed for both consumer and light industrial equipment, the devices address a growing need for compact, energy-efficient motor solutions as electrification accelerates across appliances and automation systems.

At the core of the launch is an emphasis on flexibility. The motor drivers support multiple H-bridge configurations, allowing designers to drive single or dual brushed DC motors, bipolar stepper motors, or solenoids using the same platform. This adaptability makes the devices suitable not only for fresh designs but also for redesigns and derivative products where board space and component reuse are critical.

The key features are:

- Ultra-low standby current for energy-efficient operation

- Flexible H-bridge configurations (single or dual channel)

- Support for direct PWM and constant-current PWM control

- Wide voltage and current handling for consumer and industrial use

- Reduced external components for compact PCB designs

Power efficiency is a key highlight. The ICs achieve near-zero standby current, enabling appliances to meet increasingly strict energy regulations and reducing idle power losses in always-connected systems. This characteristic is especially relevant for white goods and office equipment that spend long periods in standby mode.

The products also reduce design complexity by minimizing external components. Integrated H-bridge architectures eliminate the need for additional boost circuits, helping engineers shrink PCB size and shorten development cycles. Support for direct PWM and constant-current PWM control further broadens their usability, covering applications that range from simple speed control to torque-sensitive operation at low speeds.

With voltage ratings extending from low-voltage consumer systems to higher-voltage industrial setups, the motor drivers can handle everything from fans and valves to small conveyors and automated doors. Low on-resistance designs help reduce heat generation, improving reliability in compact enclosures.

Overall, the launch reflects a broader trend in motor electronics: higher integration, lower power loss, and greater design reuse. For engineers developing next-generation appliances or compact automation equipment, these motor drivers offer a practical balance of efficiency, flexibility, and simplified implementation.