A new high-sensitivity Barkhausen noise measurement system developed at Tokyo University of Science uncovers the true cause of excess eddy current losses in soft magnetic materials, paving the way for smaller, lighter, and more efficient transformers, EV motors, and renewable energy systems.

A team from Tokyo University of Science has developed a wide-band, high-sensitivity Magnetic Barkhausen Noise (MBN) measurement system that sheds light on a long-standing mystery in power electronics—excess eddy current losses in soft magnetic materials. The breakthrough could directly influence the design of next-generation transformers, electric vehicle motors, and renewable energy systems.

Soft magnetic materials are crucial for power devices because they can be easily magnetized and demagnetized, making them essential for transformers, generators, and amplifiers. However, as electronics advance toward higher-frequency operation, efficiency is limited by iron losses, especially excess eddy current loss. Unlike conventional eddy currents that behave like swirling water flows, these losses are linked to the irregular movement of magnetic domain walls, or DWs, which are boundaries between magnetic regions. Until now, existing measurement systems lacked the frequency coverage and sensitivity needed to clearly capture this motion.

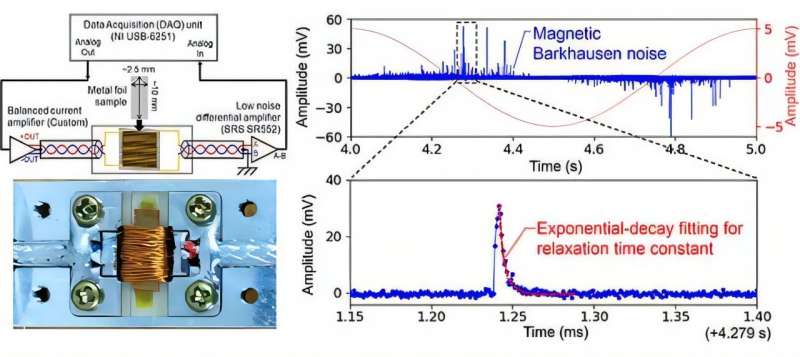

To address this, Assistant Professor Takahiro Yamazaki’s team designed a novel MBN system that combines a dual-layer coil jig, full electromagnetic shielding, and a custom low-noise amplifier. This setup minimizes interference while enabling wide-band measurements, making it possible to detect individual MBN pulses with high fidelity. Tested on Fe–Si–B–P–Cu (NANOMET) ribbons, the system revealed domain wall relaxation behavior with unprecedented precision, offering direct experimental evidence that had never been achieved before.

The study produced a key finding: excess eddy current losses are not driven by the intrinsic viscosity of domain walls, as earlier models suggested, but by localized eddy currents generated during wall motion. This changes the way researchers understand and design soft magnetic materials. Further experiments on heat-treated nanocrystalline NANOMET ribbons showed smoother domain wall motion and reduced Barkhausen noise, proving that microstructural control can effectively cut energy loss.

These insights offer industries a clear advantage. By controlling domain wall relaxation, manufacturers can design magnetic materials that minimize heat loss, reduce component size, and enable lighter, more compact devices. The applications are wide-ranging, from high-frequency transformers to electric vehicle motors and renewable energy systems—technologies critical to sustainable power. As Dr. Yamazaki notes, the system makes it possible “to measure what was once unmeasurable,” paving the way for ultra-efficient power electronics.