The new cathode and polymer design has delivered the first fully stretchable OLED stack, opening the door to skin-like screens for wearables, medical diagnostics and soft robots.

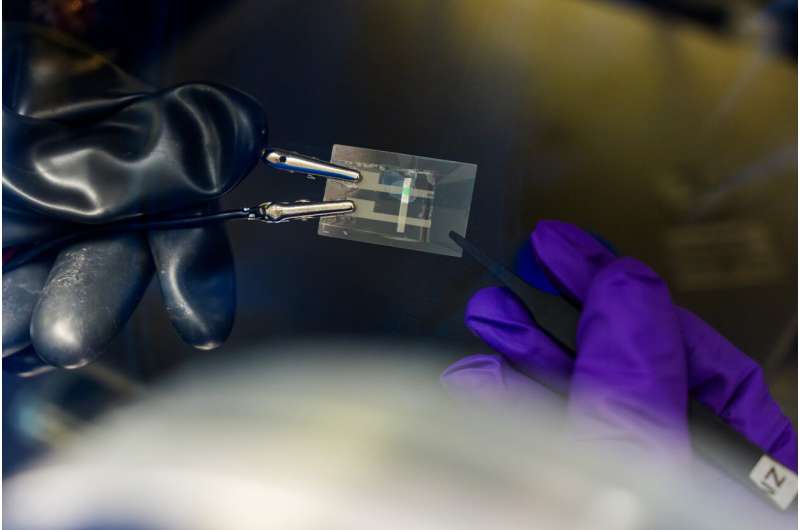

Researchers at the University of Chicago have addressed two of the most stubborn material challenges holding back fully stretchable OLED displays, marking a major step toward screens that can seamlessly wrap around curved, soft or moving surfaces. The new work delivers stretchable versions of the cathode and the electron-transport layer (ETL)—the last remaining rigid components in an otherwise flexible OLED stack. Solving these two bottlenecks significantly strengthens the case for next-generation displays designed for wearable electronics, medical patches, soft robotics and skin-like interfaces.

The most unexpected advance comes from a counterintuitive use of liquid-metal embrittlement, a phenomenon typically known for damaging metals. Standard OLEDs use aluminum as the cathode material, but aluminum does not naturally stretch without breaking. Instead of trying to prevent breakage, the UChicago team engineered a controlled version of it. They embedded an ultrathin aluminum film into an elastic substrate and then exposed it to a specially formulated gallium–indium liquid-metal gel. This triggered micro-cracks that open and close as the device stretches and relaxes. Crucially, these cracks do not sever the electrode; the liquid metal flows into gaps and reconnects pathways, keeping electrical performance stable. Month-long aging tests showed no significant drop in conductivity, demonstrating that the engineered “crackle” effect is both repeatable and reliable.

The researchers also solved the brittleness of the electron-transport layer, which guides electrons from the cathode into the emissive part of the OLED. The team developed a new polymer family built from conductive triazine-based rings linked with flexible alkyl chains. Adjusting the balance between the rigid conductive groups and the softer chains allowed them to fine-tune a material that remains elastic while still efficiently moving electrons. This tunable design makes it possible for the ETL to stretch without compromising brightness or efficiency.

Together, the stretchable cathode and ETL complete what the team describes as a truly elastic OLED stack—something that had not been achieved despite years of progress in flexible materials. The researchers now aim to push these materials toward commercial-grade performance, envisioning future displays that conform to the body, integrate into medical diagnostics or enhance lifelike movements in humanoid robots.