AR glass could get cheaper, lighter and clearer lenses made with this new technology

Creating an Augmented Reality (AR) waveguide, generally expensive and requires highly precise equipment to produce. To overcome this obstacle, scientists from the University of Melbourne, Australia, developed a prototype that reduces the fabrication cost of the important layer in manufacturing AR glass, called the Waveguide.

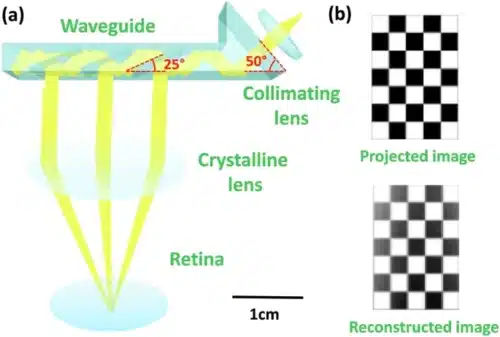

A waveguide is an optical component that merges projected images of surrounding lights. It’s a key part of the optical-see-through near-eye display while wearing the AR glasses. It basically allows light from the environment to pass through via total internal reflection to the user’s eye, to make the visual content appear in the glasses and to able to see the real world at the same time.

What’s different about this new Liquid Optical Waveguide is the use of silicone oil as the optical medium. Also, using PolyJect 3D printing on the waveguide frame, filled with he liquid to complete the whole process.

This method eliminates complex and high-precision steps which are previously needed in the fabrication process of dicing, layer bonding and polishing, used in Solid Waveguide manufacturing.

Liquid Optical Waveguide simplifies problems like reflectors and bending, which are common in Solid Waveguide and offers self-healing capabilities to minute scratches up to an extent, which was not possible previously.

The design process of the Liquid Optical Waveguide involved a 3D printing frame filled with silicone oil, sealed with glass. which then optimised with COMSOL Multiphysics, a simulation software, features a triangular prism for light coupling and dielectric reflectors, optimising the waveguide to refract the surrounding light into the user’s eye.

This prototype, weighing 5.4 grams, proved to maintain over 77 per cent of light from the surroundings, creating a clear image of the surroundings, viewed from the AR glass.