New low-damping control method sharpens force tracking and stability in collaborative robot electronics.

A research team has announced a breakthrough in impedance control for collaborative robots (cobots), tackling a persistent challenge in industrial electronics that hinders precise, high-speed interaction under variable force conditions.

Cobots are increasingly deployed in tasks like impact riveting, resistance spot welding, and precision assembly jobs that require both rapid response and compliant, stable interactions with unpredictable forces. Traditional impedance control schemes struggle here, suffering from large force-tracking errors and instability when damping is low, a combination that compromises performance and limits real-world industrial adoption.

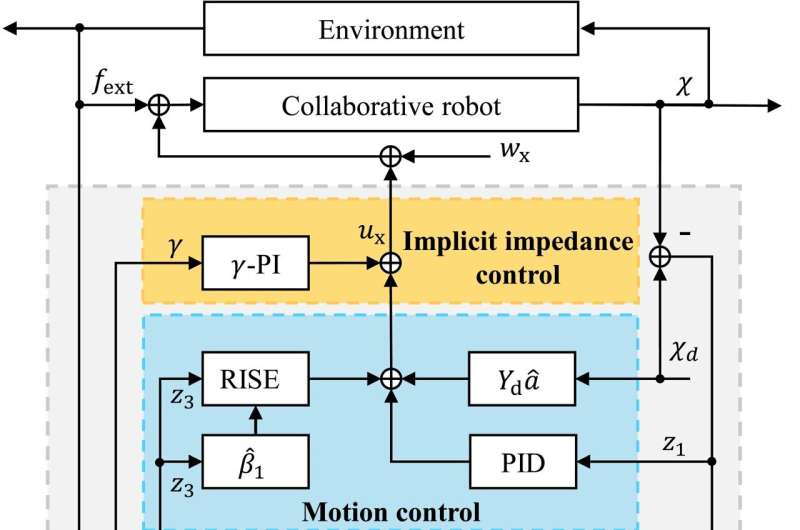

To overcome these limitations, scientists from the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences and collaborators at the University of Liverpool developed an adaptive jerk control (AJC) system built around what they call a biased sliding surface (BSS). This innovative control architecture continuously monitors the dynamic relationship between force and position in cobot systems, even under low-damping conditions that traditionally introduce significant uncertainty.

The core advance lies in the controller’s ability to estimate and exponentially attenuate force offset errors in real time. By broadening the range of impedance parameters that maintain system stability, the new method enables robots to sustain high stiffness without sacrificing responsive compliance crucial for sensitive electronic tasks and human–robot collaboration.

In lab trials, cobots equipped with this control strategy demonstrated improved force-tracking accuracy and enhanced contact stability compared with existing impedance-control approaches. These improvements are especially relevant for electronic systems and automation platforms where precise force modulation impacts overall performance and safety.

The team’s findings, published in IEEE Transactions on Industrial Electronics, suggest this control framework could accelerate the integration of cobots into high-end manufacturing and advanced human–robot interaction applications, boosting productivity while maintaining tighter control over electronic actuation and sensing interfaces. The research offers a significant step forward in electronic control systems for robotics, resolving longstanding impedance-related constraints and enhancing the robustness of collaborative automation technologies.