Some everyday lotions and gels quietly hold hidden stresses from mixing. These invisible forces can change their texture over time. Discover more!

Credits:Credit: Courtesy of the researchers

Hand lotions, hair gels, and shaving creams can become runny because they retain “mechanical memory” from the mixing process. These materials can hold internal stresses that cause them to shift back toward their original, pre-mixed state, even after setting.

An MIT engineer developed a way to measure these residual stresses in soft materials. Research shows that products like hair gel and shaving cream can hold these stresses longer than manufacturers might expect. Using a standard benchtop rheometer, MIT postdoc Crystal Owens found that gels mixed in one direction keep a memory of that direction. Even days later, internal stress can make the gel return to its earlier state.

Hand lotion, hair gel, and shaving cream are examples of soft glassy materials, which combine properties of solids and liquids. They can be poured like a liquid yet hold their shape like a solid, existing in a balance between solid and liquid. In manufacturing, ingredients are mixed into a uniform product, and quality control assumes that any residual stresses dissipate within about a minute. Experiments suggest these stresses can persist after the material appears to settle.

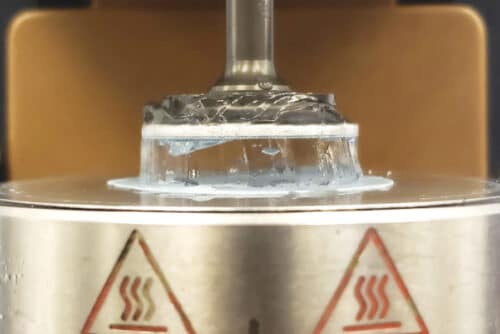

To investigate, researchers conducted experiments on soft glassy materials using a rheometer, an instrument with two rotating plates that can twist and press a material at precise pressures to measure internal stresses and strains. Each material was placed in the rheometer, mixed by spinning the top plate, and then allowed to settle for longer than typical quality control periods. The force required to hold the material in place indicated the amount of residual stress present.

These experiments showed that soft glassy materials can retain residual stress after they seem stable. The degree of stress depends on the direction and timing of the initial mixing, meaning the materials “remember” how they were processed.

Researchers also developed a model to estimate how a material will change over time based on its residual stress. This approach could help design materials with minimal residual stress, ensuring they remain stable for longer periods. One application is asphalt, which is mixed, poured, and allowed to cool and settle over time. Residual stresses from mixing may contribute to cracks in pavement, and reducing these stresses early could lead to longer-lasting roads.