Sensors have revolutionized the life around us. Sensing has enabled industrial advances, such as the technology involved in building and factory automation. The recent advancement in sensor technology has made a massive impact in the personal electronics and medical field.

What exactly are these sensors? Sensors are devices which detect changes in the environment and communicate these changes to another system over electrical or optical means in order for the system to respond to the changes.

Inductive, capacitive & magnetic (hall-effect) based sensing are some general sensing technologies which can be used to solve a variety of challenges.

Inductive Sensing

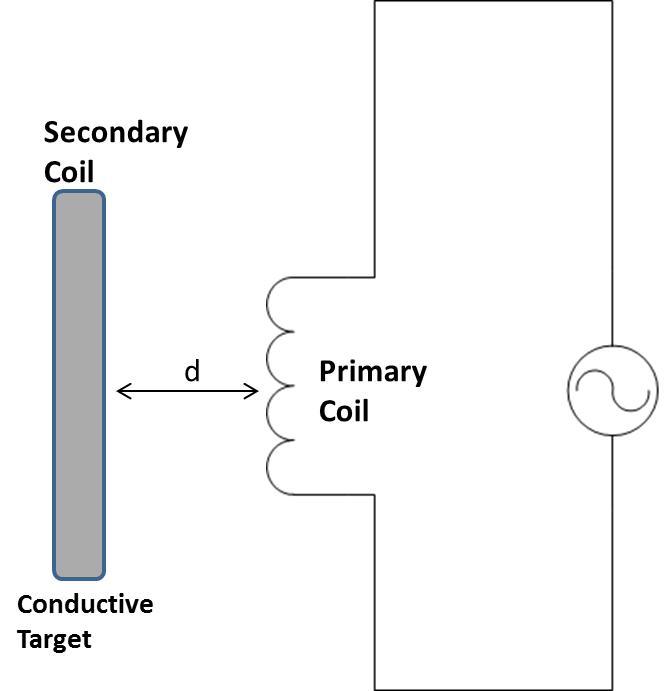

Inductive sensing is a contact-less sensor technology that enables sensing of conductive (metallic) targets. Inductive sensing is based on the concept where the AC current flowing through the primary coil generates a magnetic field around it. (Refer to Fig. 1) If a secondary coil (conductive target) comes in the vicinity of the primary coil, the primary magnetic field will generate eddy currents in the secondary coil. The magnitude of eddy currents will depend on the size, composition and distance of the secondary coil. These eddy currents generate its own magnetic field which opposes the original magnetic field in turn changing the inductance and A.C resistance present on the primary coil.

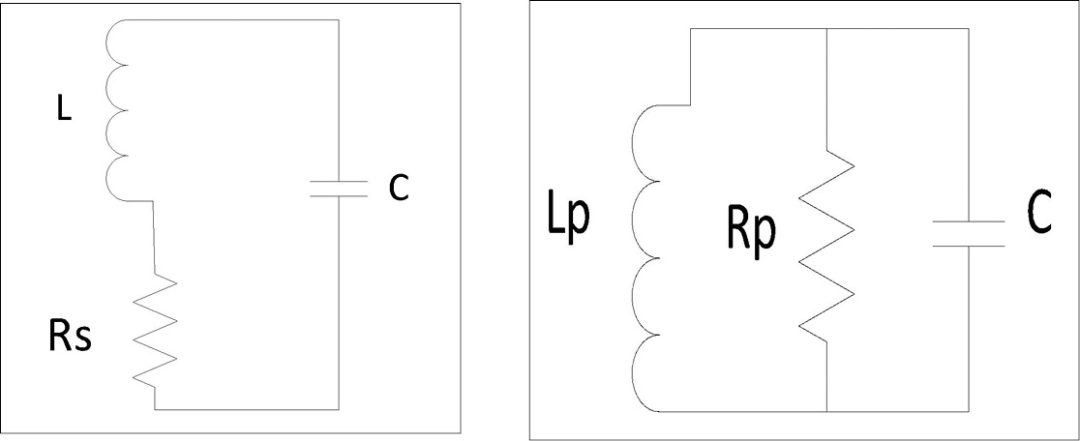

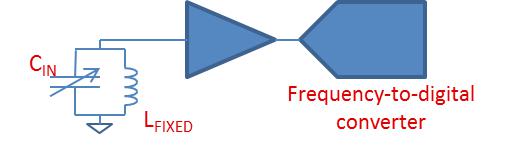

The primary coil (sensor) can be modeled as below. (Capacitor C is external to the inductive sensor)

By measuring inductance (L) and AC resistance (Rs) of the primary coil, we can use TI’s LDC (Inductance to Digital Converter) in numerous applications such as seat-belt buckle detection, rotary dial, metal keypad and gear counting.

An innovative application of inductive sensing is in the volume knob control in vehicles. (Refer to Fig 3) This is a case of incremental position encoder where the LDC tracks inductance which results in appropriate volume change. This is a contact less based solution which solves the problem of frequent replacement of mechanical components due to wear and tear.

TI’s new LDC1101, High-Speed Inductance to Digital converter has made an architectural change by combining the best features of previous generation’s LDC1000 and LDC161x. LDC1101 features dual inductive measurement cores, allowing for greater than 150ksps 16-bit Rp and L measurements simultaneous with high resolution 24-bit L measurement. LDC1101 also includes a threshold-compare function that enables accurate measurement of speed and linear/angular position in applications of motor speed and position determination. LDC1101 runs at a voltage of as low as 1.8 V which enables to reduce the power consumption of the system significantly.

Capacitive Sensing

Capacitive sensing is a technology based on capacitive coupling where the target material (conductive or non-conductive) changes the electric field around the primary sensor where the target material has different dielectric constant than air. This primary sensor could be copper on PCB, a piece of metal or conductive ink.

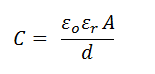

The sensing capacitance C can be represented as below:

Where:

: Permittivity of free space (8.854 x 10-12 F/m)

: Dielectric constant of material

A: Area of sensor electrode plate

d: Distance between electrode plates

Change in capacitance is dictated by , dielectric constant of the material if plate area and the distance between the plates are kept constant.

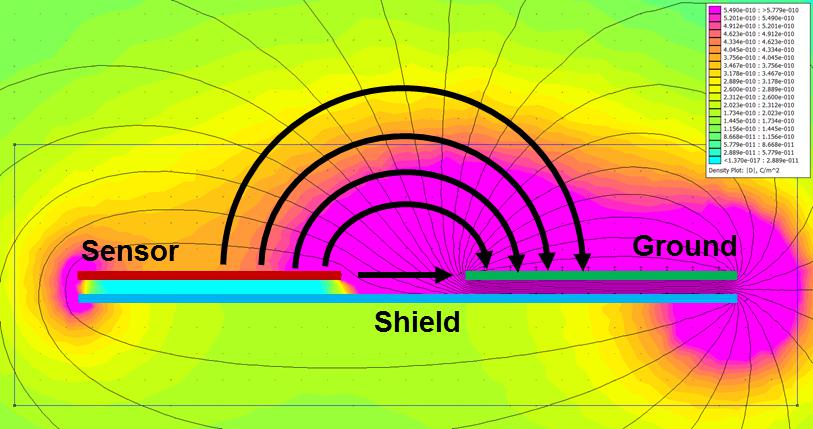

The below figure shows the density of the electric field lines around the electrodes.

Field lines within the inner edges of the plates dominate the capacitance measurements (purple region). This is where the target material causes maximum change in capacitance.

This change in capacitance can be used in various applications such as proximity sensing, collision avoidance, liquid level sensing etc.

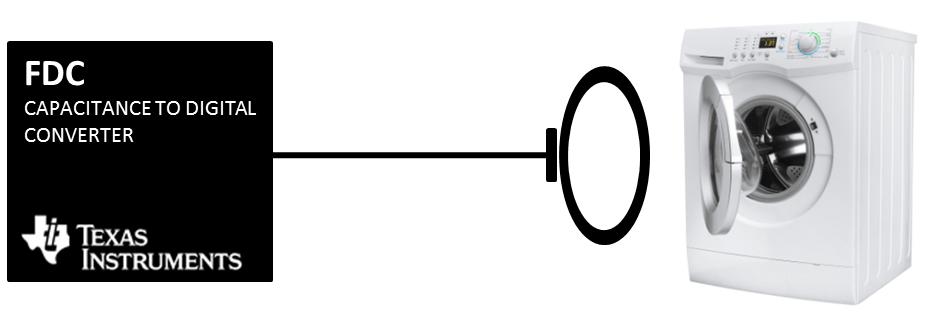

An innovative method of using capacitive sensors is for safe, secure door closure application as in a case of a washing machine (Fig 5). The capacitive sensor placed just inside of the washing machine where the door closes can be used to indicate a warning in case of improper door closure depending on crossing of set capacitance threshold.

TI’s FDC2x1x family of Capacitance-to-Digital converter has a unique architecture which enables EMI resistant proximity sensing and fast sensor excitation rate for level sensing of any liquid including conductive liquids such as soapy water and ink. This has been possible due to an oscillation based architecture with high-Q narrowband band pass filter which has strong noise rejection.

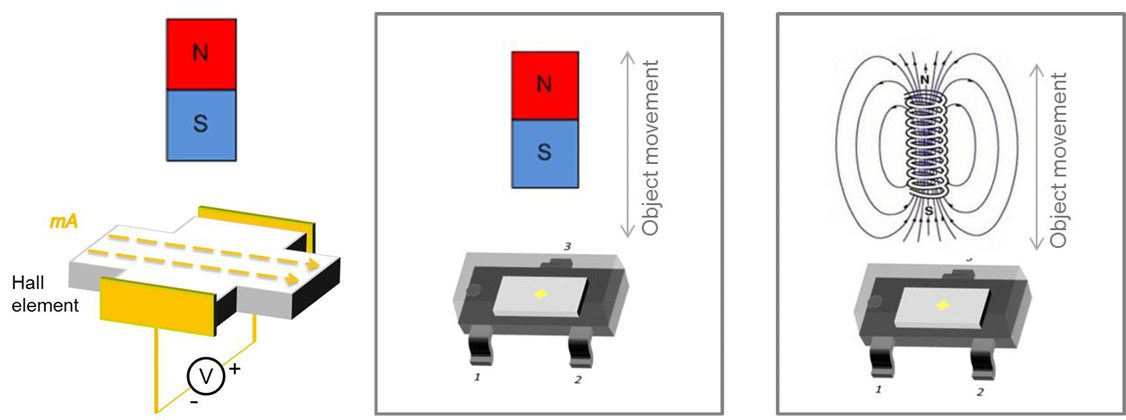

Magnetic (Hall Effect) Sensing

Magnetic sensing on the silicon is achieved by making a Hall element with a p-type substrate such as GaAs, and giving it a current bias. In the vicinity of a perpendicular magnetic field, the electrons (hole) experience the Lorentz force and result in a voltage bias (Hall voltage) across the hall element.

TI parts such as DRV5013, DRV5023 & DRV5053 etc are based on the above principle and are used in applications such as speed, contact, position, acceleration sensing worldwide.

Popular requirement: Magnetic tamper detection in energy meters – can be implemented using DRV5033, an omnipolar switch hall effect sensor.

Application Specific sensing products

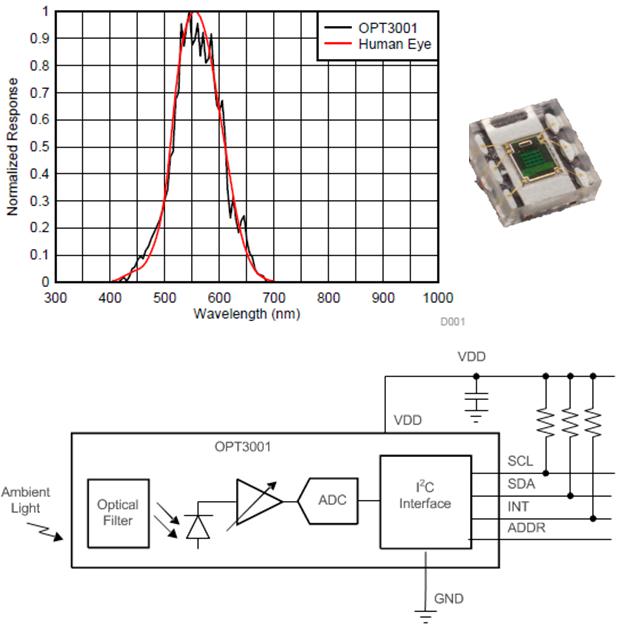

Ambient Light Sensing – OPT3001

The OPT3001 was developed to take on the challenges faced by other Ambient Light Sensors (accuracy & IR leakage, dynamic range, power, and ease of use). The OPT3001 provides an accurate metering of light intensity that approximates the sensitivity of the human eye. The OPT3001 directly reports out the Lux level matching the light intensity a human is experiencing regardless of light source (sun, incandescent, florescent, CFL, LED). Its auto-gain feature dramatically simplifies system development and can provide effectively 23-bits of resolution from 0 Lux to 83K Lux. OPT3001 provides an incredible resolution and accuracy even in systems where the industrial design hides the ALS behind dark glass for aesthetic purposes.

Humidity Sensing

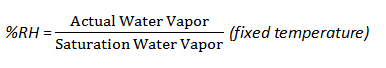

Humidity is the amount of water vapour present in air. Relative humidity is a way to express humidity. Relative humidity is the ratio (at a fixed temperature) between actual water vapour and saturation water vapour, expressed as a percentage. (Saturation is the point where the water vapour starts to condense.)

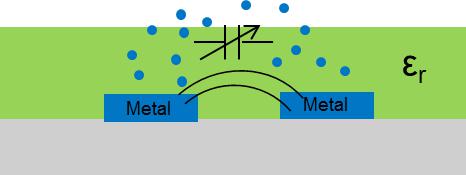

The working principle of the humidity sensor (RH sensor) is similar to the capacitive sensing technique. The water vapour (humidity) is absorbed by a RH sensor layer between 2 metal plates. This changes the fringe capacitance b etween the plates and thus the supporting electronics change this capacitance value to a Relative Humidity value.

A challenge faced here is the dust that can get deposited on top of the sensor. This can incorrectly trigger a change in the fringe capacitance, reduce the sensitivity towards the water vapour or completely block the sensor.

The HDC100x series of humidity sensor intrinsically protects the sensor from any dust because the sensing RH layer is present below the die and not exposed to the external environment. These sensors are suitable for use in wearable devices due to their small footprint and low power consumption. A project on humidity sensor is also available if you want to try

Temperature Sensing

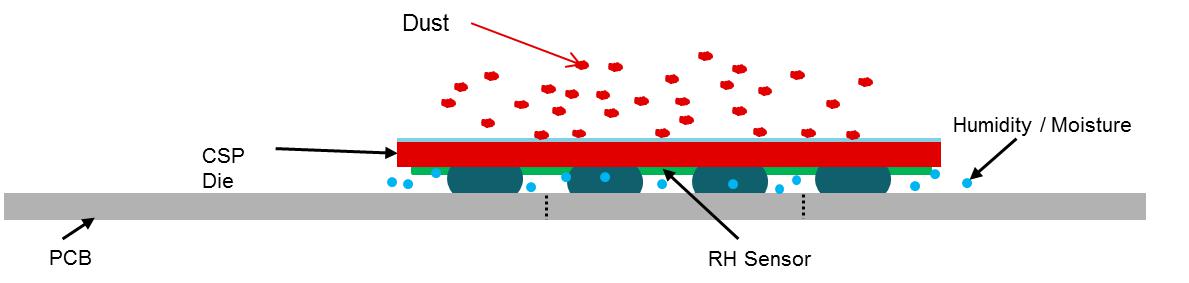

With the traditional contact based temperature sensing products in Texas Instruments, there are also certain non-contact temp sensors. Leveraging MEMs technology, TMP006 is a revolutionary step forward in Passive IR (PIR) sensors. The TMP006 is the first device to integrate an on-chip thermopile, which dramatically reduces the space and costs of contactless temperature measurements. The TMP006 is 23 times smaller and a fraction of the cost of other Passive IR solutions. TMP007 is the next gen device which integrates the Math engine i.e. directly reads out the temperature value.

Heart Rate Sensor for Wearables

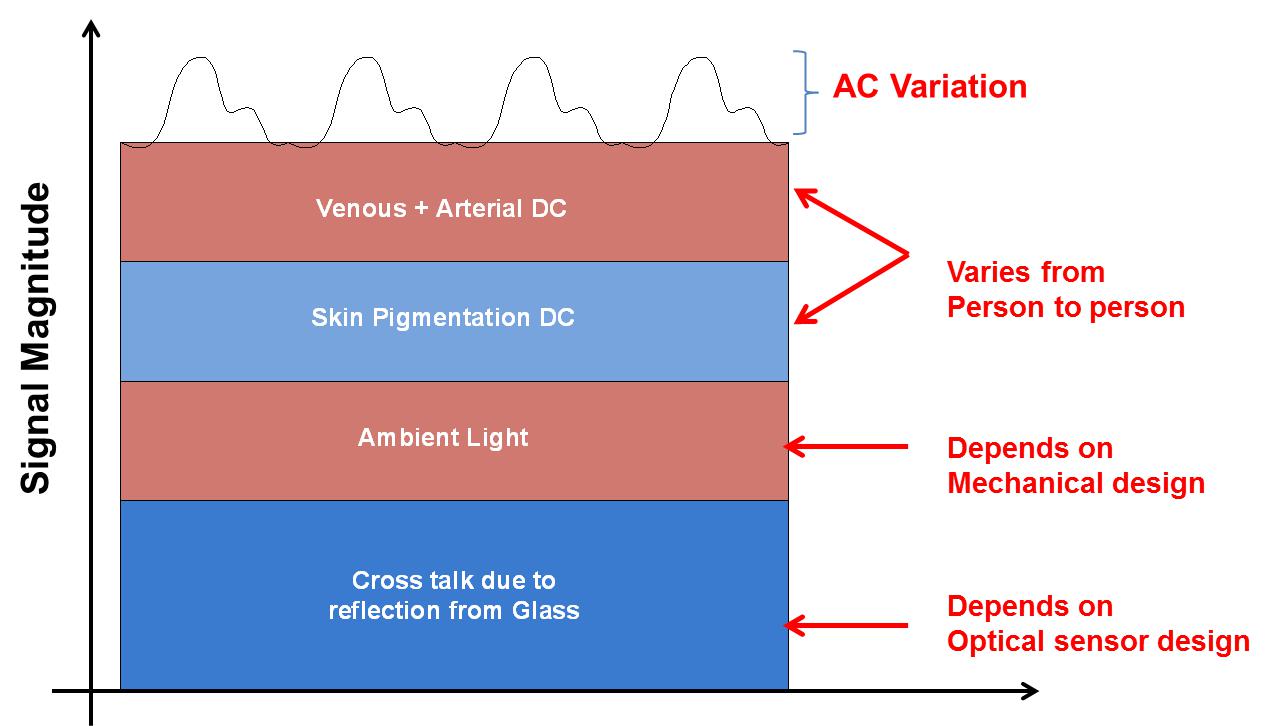

The optical system for heart rate measurement in wearables (example: smartwatch or activity tracking bands) consists of LEDs that shine basis the light on the skin and a photodiode that receives the reflected light. The photodiode and the LEDs are on the same side and the photodiode collects the light reflected from the blood in the arteries, veins and the skin tissue from various depths. The blood flowing in the arteries and veins is heartbeat induced or pulsatile in nature in enable changes in the reflected light with time. Thus this photodiode signal can read the instantaneous heartbeat of a person. The AFE4404/03 devices from TI are the lowest power devices that provide solutions for heartbeat monitoring.

The AFE4403/04 separates the DC signal from the AC variation. It cleans and amplifies the AC signal and passes it further for processing towards skin tone cancellation, motion cancellation, etc.

excellent

Thank you for the feedback.