The pandemic has led almost all the major industries to heavily rely on technology. Every industry has seemingly geared up this adoption in order to operate with will force. With the introduction of Industry 4.0 the human involvement in accomplishing sophisticated tasks will be strongly limited and will save a lot of cost, time and energy. Continue to read to know about this progression…

It just seems like a lifetime ago but it was actually only till two years back when digitisation was in conversations all the time in India and many other countries. We knew technology was important but we would also become quite complacent with how we have always lived and done our business. Pandemic came along and rendered most traditional systems redundant. It led technology to suddenly become the safest port in the proverbial storm. Now, businesses and governments have experienced the incredible and prolific possibilities of technology. India’s transformation into a leading knowledge economy is well on the way. A lot of it will be driven by or centered around Industry 4.0 as it is the only way to make India’s manufacturing industry more efficient and competitive while also solidifying India’s place in the next manufacturing leader.

The world as we knew it, is disappearing

Emerging trends are appending established orders. While that can be very chaotic, it can also be incredibly transformative. The way we work has changed forever. We are becoming increasingly hybrid as employees are demanding more choices and flexibility to do work while leaders are now looking beyond geographies to hire more diverse talent.

Some rudimentary jobs are being replaced or enhanced by automation for instance, robots are now serving coffees at Barista, customer services are being done by artificial intelligence (AI) bots and so on. There’s a potential to create 90 million jobs that are also remote in nature. At the same time, new business models are also emerging across sectors with companies opting for digital delivery, digital delivery platforms, augmenting the existing ones with technologies like AI, machine learning (ML) to make experiences more intelligent and human. So, all of these digital models are accompanied by a rising wave of automation also. Infact, the world economic forum believes that machines will do more work than humans by 2025. Since the call for local and accelerated innovation has never been louder. And Indian startups are definitely responding to that in a very big way too as there were 42 unicorns that were born just last year alone. Startups are also recording a high level of investments. Today, business leaders are questioning the purpose of their companies and their existence as a whole. Stakeholder capitalism is seemingly becoming just as critical for businesses as any other traditional parameter. Leaders have to act now in order to create more resilient agile and responsible businesses in today’s competitive world.

Time is of the essence

Look at any major industry today such as mobility, health care, education etc. There are two or three incumbents in these industries that are mostly platform players and they dominate the market. McKinsey & Company says that 95 percent of the economic profit is earned by the top 20 companies alone. In this winner takes all paradigm the growth and evolution of a business determines the leading player.

It can be broadly categorised into three phases such as short term (12 months) , mid term(one to three years) and long term (three to five years) timeframe. Following are the phases:

- Respond phase (short-term): it is the ongoing phase as companies decommission redundant departments, reinvest in digital capabilities, switch to digital business models. If you look at us at Cisco, we started out as a hardware focused company but over the past few years especially during the pandemic we have been transitioning the majority of our portfolio to be delivered as a service to give our customers more flexibility while making a purchase. That is why we have been able to get a whole host of consumers from both small and medium sized businesses.

- Reflect (mid-term): The pandemic has shown us how uncertain things can be. We are supposed to be adaptive enough to turn these odds into our favor. It begins with fostering agility and resilience at every level of the organization. This is where technology can be incredibly effective. It could mean a complete overhaul of a product line, adding new digital products or augmenting existing ones. However, rescaling of the workforce is an imperative that every business must undertake to be ready for any challenge or opportunity that comes their way.

- Reimagine (long-term): lastly, companies need to optimise for speed. Operating models need to be frictionless to foster agility and simplicity while also enabling a network of empowered dynamic teams that includes at a company’s edge where employees are the closest to consumers. Future ready companies have to organise themselves in a way that makes them fitter, flatter and faster allowing them to unfreeze value in lucrative places. It means a simplified organisation structure that prioritises decision making, data rich platforms that allow teams to make more informed decisions etc. Let us look at this in the context of Industry 4.0 to have a better understanding.

A lot of mundane processes have already been automated to a large extent. We are starting to see predicted systems that allow companies to reduce wastage and downtime and derive far more value from the data being collected as sensors and IoT devices go mainstream. Companies have already begun to exploit these applications. For instance, during the pandemic we helped build an intensive care unit (ICU) cart to facilitate remote monitoring of isolation wards. These systems are still not highly predictive for self diagnosis. While a lot of companies are collecting a lot of data they have still not started to take full advantage of it. It will accelerate over the next few years. Remote and centralised monitoring will become far more sophisticated. Talent is a very critical aspect in order to make the most of Industry 4.0 technologies.

Artificial intelligence (AI) driven predictive and forecasting systems will come into play across production plans as the technology becomes smarter. Systems must be developed to a point where certain parameters can be changed automatically without human intervention. It will save a lot of labour cost which can be diverted into more profitable pursuits like innovation and invention. The smart factory can then transition into a primary automated operation driven by AI systems. It is normally cheaper and more efficient for workers in the mining industry and other industries as well.

Pillars of Industry 4.0

We tend to think of Industry 4.0 as a magic bullet but let us also talk about the mechanics and technologies that constitute Industry 4.0 and the impact that it can have on the supply chain. Industry 4.0 is an architect to bring multiple technologies to play for the benefits of industries which have been brought to deliver outcomes in a much smarter and efficient way which.

It is a rapidly growing field of interconnected devices. There are sensors that you deploy for asset condition, asset monitoring or energy usage. The key benefit of the internet of things (IoT) is not so much in the sensors themselves but in the course of data that it generates and turning that data into actionable insights.

Augmented reality provides additional visual data to workers to enable processes and make product improvements. One example would be the use of connected glasses to help operators fit components correctly while being guided by a remote expert.

Virtual reality comes next and it allows testing of things like ergonomics without building physical representations simulation through digital twins. Trailing new ideas in the virtual world will be more cost effective than building physical prototypes.

Then there is the field of additive manufacturing which uses 3D printers to make components faster, lighter and cheaper. It can go a long way to improving maintenance and repair operations where a replacement part could be made locally rather than being shipped from the source. Infact, the biggest buyers of 3D printers in India are dentists who are already using it to manufacture a lot of their parts by themselves at their clinics.

All of these new interconnected systems must be adequately secured against unwarranted intrusion. We know that the threat landscape is becoming more complex as digitisation and Industry 4.0 accelerates. Ensuring end-to-end security of these systems and data is a crucial step in safeguarding operations. Security can not be bouldered on, it has to be a part of the fabric from the get go. The field of system integration will play a crucial role in making sure that increased value is delivered from these newly combined technologies despite all the existing interruptions. Lastly, AI and robots are already being put to use and in future that may even advance to further levels where systems can operate independently without frequent human intervention. This could be manufacturing machines themselves or delivery platforms within the factory such as autonomous vehicles.

Future proofing India’s industries

The most important question that rises up is how do we make use of all this untapped potential? How do we mold the fourth industrial revolution into a force for change?. Now, there are five broad areas that need our attention.

Firstly, we need the right digital and physical infrastructure in place. That does need a secure and reliable internet architecture. It should be able to support more intricate applications of Industry 4.0 at a much larger scale. It means dedicated resources and space for innovation centers where new applications of Industry 4.0 can be explored and tested. All of this can only be possible if there is a conducive policy framework that encourages investments and innovation while also making it convenient for businesses to experiment with solutions and use cases.

A skilled workforce will allow organisations to gain major ground in exploring more varied use cases and this is where perhaps India and many other countries will face their biggest challenge. A recent report by NASSCOM-Zinnov says that India will face a shortage of upto 1.9 million techies by 2026.

And lastly, we have to get things done in the most sustainable way possible. This is not just about the environment but about doing things in a way that optimises resources and ensures long-term growth particularly in a country that is always burdened with shortage of all kinds of resources.

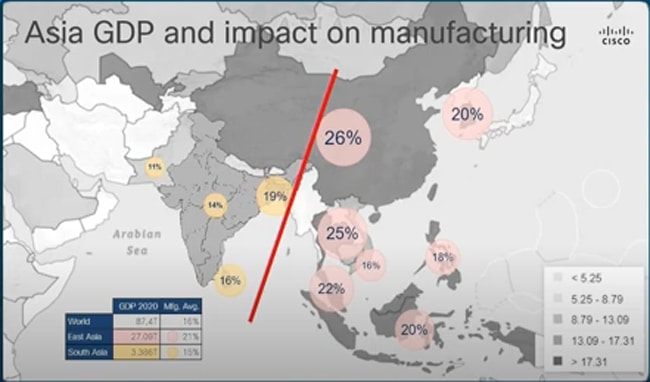

Asia’s GDP and impact on manufacturing

Manufacturing is our race in the world. It can be the biggest driver of the five trillion economic vision that India has. However, we need to make major efforts to boost its contribution to gross domestic product (GDP). In India, the manufacturing contribution to GDP has stagnated in the 14 to 16 percent range.

If you look at this map above (figure 1), two clear groups emerge not just in terms of geography but also in terms of their contribution of manufacturing industries to the GDP. The circles in pink are all above 16% with China being the leader with over a quarter of their GDP from manufacturing. In contrast, not only south asia is lagging behind as a region but India is one of the lowest within this group as well. It is quite ironic because India’s GDP is expected to grow at a higher rate than any other country. A recent report by global data suggests that India’s manufacturing GDP is forecasted to remain below that of asian nations over the next few years till 2026. It is where Industry 4.0 can help us flip the script. It can enhance every touch point of industrial production including last mile delivery.

Balancing purpose and progress

It is evident that the pandemic has united us and also reminded us that progress can not take place if it does not include everyone. Companies must also assess what they stand for and who they really are. The time when business was just about the revenue is over. To ensure sustainable growth companies need to work towards strengthening the triple bottom line. It is one the key factors in earning stakeholders trust and loyalty in the new normal and that in-turn can catalyse long-term prosperity.

In the end, we should know that the road ahead of us is replete with opportunity. We are at a major turning point in India’s transformation and we know that Industry 4.0 is going to play a major role in this journey. We must balance progress with purpose as we endeavour to bring new possibilities of technology to life and ensure that our work is inclusive and sustainable for everyone.

Laveesh Kocher is a tech enthusiast with a keen interest in tech and open source. This piece is inspired from a talk by Daisy Chittilapilly, president, CISCO, at VLSID 2022.