Researchers at Guangdong University of Technology have developed an ultra-compact, metal-free thin-film supercapacitor stack that outputs 200 volts—using laser-induced graphene and no traditional wiring.

In a leap toward compact and efficient energy storage, researchers at Guangdong University of Technology (GDUT) have engineered a groundbreaking thin-film supercapacitor (TFSC) stack capable of delivering 200 volts—all within just 3.8 cm³. Even more impressive? The design eliminates metal components entirely, replacing them with multifunctional graphene derived from laser-treated polyimide.

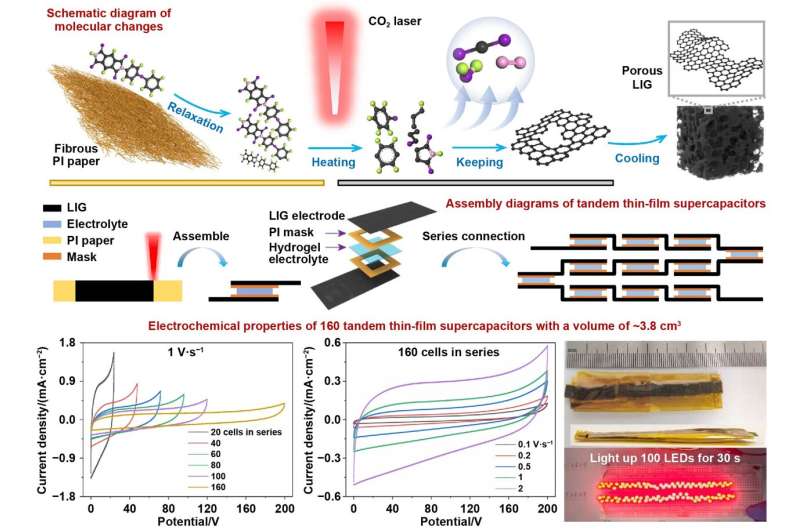

The study details how the team used a standard CO₂ laser to transform commercial polyimide (PI) paper into 3D graphene—a material known for its high conductivity, flexibility, and energy storage capabilities. This laser-induced graphene (LIG) acts as electrode, conductor, and structural support all in one—simplifying the design and slashing the bulk of conventional supercapacitor architectures.

The team fine-tuned laser parameters like power, speed, and scan density to optimize graphene quality, achieving low-resistance, high-surface-area sheets. These sheets, layered with a hydrogel electrolyte that also serves as a separator, form the foundation of the compact supercapacitor stack. With each individual TFSC cell measuring just millimeters, the researchers stacked 160 such units to reach the 200V milestone—enough to briefly power 100 LEDs or a 3-watt bulb.

This design completely removes the need for external metal connectors. That means reduced cost, fewer failure points, and a much smaller footprint—ideal for space-constrained or extreme environments.The TFSCs demonstrated strong and stable performance across the stack, with uniform electrical behavior from cell to cell. Next steps for the team include boosting energy density and expanding the voltage window even further.With potential applications in wearable tech, flexible sensors, and harsh-environment electronics, this innovation is a significant step toward scalable, lightweight energy storage solutions that break free from traditional form factors.

“Traditional designs are burdened with metal current collectors and complex wiring to string multiple cells together,Our method integrates the core functions into a single material and process, creating a lighter, more scalable system.” said Prof. Huilong Liu, the paper’s corresponding author. ”