Research outcome could revolutionise the smartphone and wearable technologies. Traditional conductive polymers were lacking some potential, which this research fixes.

Scientists at La Trobe University have developed an ultra-thin, highly durable conductive polymer by applying hyaluronic acid directly onto a gold-plated surface, a method that could revolutionise the performance, manufacturing capacity, and affordability of smartphones, touchscreens, wearable technologies, and next-generation interactive electronics. The technique could prove ideal for applications in biosensors and advanced electronic devices.

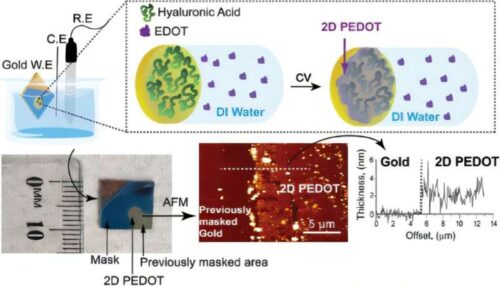

The ‘tethered dopant templating’, as the name given by research team, is a robust way of making a conductive polymer having flexibility, durability, and scalability. The technique enables unprecedented control over electricity and metal conduction, and also can be reproduced as and when needed.

“This breakthrough has the potential to significantly enhance the functionality, affordability, and ease of use of devices ranging from medical wearables to interactive displays,” said Associate Professor Wren Greene, who led the study.

The resulting material, 2D PEDOT, is invisible to the naked eye yet powerful, with scientists able to precisely control its properties, shape, and appearance. The polymer can be reproduced at scale and retains both metal and electricity conduction.

Conductive polymers have existed for nearly 50 years but remain difficult to fabricate, often lacking transparency, displaying inconsistent properties, and conducting electricity poorly. This research overturns the long-held belief that hyaluronic acid must be mixed with water and polymer-forming particles, proving it can be applied directly.