Yokohama National University researchers have developed an untethered acoustic levitation device that zips in any direction at over 3 m/s — no wheels, no cables, no friction.

Researchers at Yokohama National University have unveiled a contactless transport — an untethered levitation device capable of omnidirectional, ultrafast movement without the drag of friction. Unlike conveyor belts or traditional mechanical carriers, which lose speed and precision to friction, this innovation enables smooth, agile, and precise movement for small components in machine assembly, biomedical, and chemical applications.

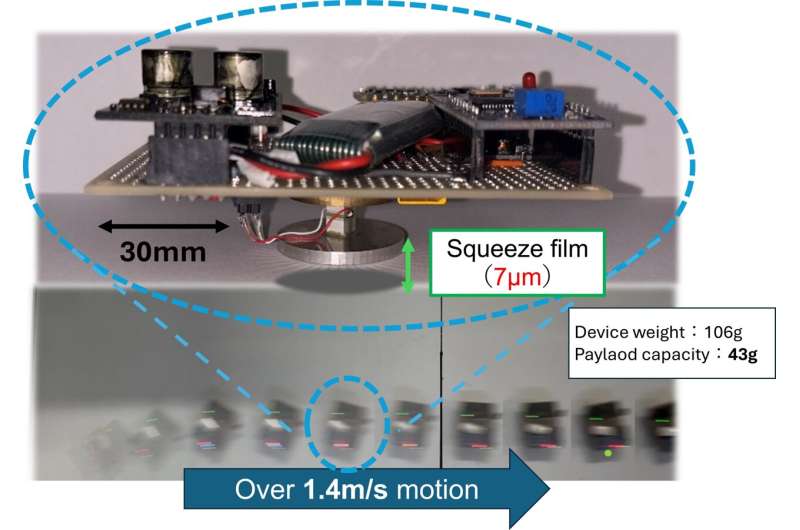

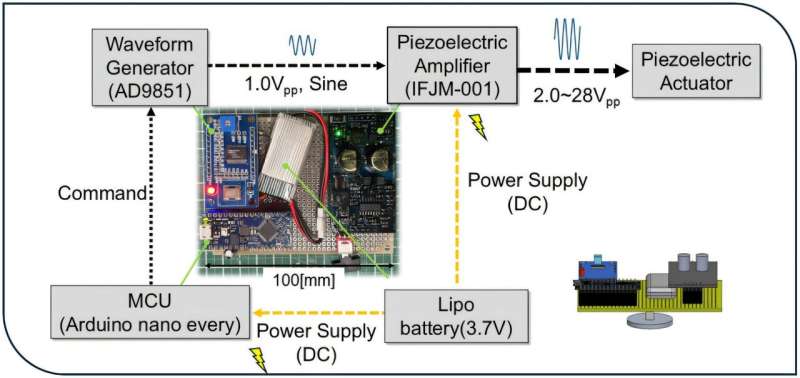

The device uses acoustic levitation — suspending objects in mid-air via sound waves — to overcome friction. Conventional acoustic systems rely on cumbersome cables that interfere with positioning. This design eliminates that limitation with a wireless drive circuit, ensuring stable levitation height and rapid, controlled movement. Experimental trials confirmed speeds of over 3 m/s on inclined surfaces. At a 10° slope, the device glided effortlessly when levitating, while gravity completely halted it when levitation was off — a definitive proof of its frictionless operation.

It also demonstrated the ability to carry loads up to 43 g in addition to its own weight (150 g limit), maintaining full levitation and maneuverability. The structure integrates a piezoelectric actuator, converting electrical energy into mechanical force, creating a “squeeze film” of fluid between surfaces. This allows truly omnidirectional motion without tethers or external magnetic/gas generators — challenges that hinder diamagnetic and pneumatic levitation.

This cable-free, high-speed levitation platform promises a leap in micro-transport technologies. For manufacturers, it could revolutionize machine part assembly lines by enabling faster, cleaner, and more precise handling. In biomedical labs, it offers contamination-free transport of sensitive cells or micro-samples. In chemical processing, it enables non-contact transfer of reactive or delicate materials.

Looking ahead, researchers plan to improve levitation efficiency, load capacity, and stability on uneven surfaces. The long-term vision includes robotic systems built from multiple levitation units, coupled with propulsion mechanisms, for fully autonomous, contactless delivery systems.

“This device merges high-speed transport with stability and complete freedom from cables — a first in its class,” says associate professor Ohmi Fuchiwaki. “We see applications wherever precision, cleanliness, and speed are critical.”The work, published in Advanced Intelligent Systems, marks a significant step toward practical, scalable frictionless transport solutions for the next generation of miniaturized technology.