Sensors designed for precision, durability, and compactness can enhance everything from factory robotics to EV steering systems and smart home devices.

Littelfuse, Inc. has recently launched two new Tunneling Magnetoresistance (TMR)-based magnetic angle sensors, namely LF53466 and LF53464. The manufacturer highlights their advantage over Hall-effect devices, citing superior thermal stability, broad voltage compatibility, and higher measurement accuracy.

These sensors, as told by the manufacturer, are especially designed for high-precision (0–360°) angular measurement with minimal thermal drift. These sensors are crafted for delivering accuracy even in harsh environments. In industrial automation and robotics, the sensors can enable precise rotary position tracking, absolute angle measurement, and smooth control for robotic arms or joysticks in advanced machinery. If integrated, they can also support accurate steering angle detection, pedal position monitoring, and efficient motor control in e-bikes, two- and three-wheelers, as well as construction and off-road EVs.

They can also be utilised into power tools, smart thermostats, and home appliances, handling knob and valve position sensing for intuitive control. Within precision control systems, they promise to deliver high-resolution feedback for rotary encoders, contactless potentiometers, and critical angle sensing in motor feedback loops, valve actuation, and human–machine interface setups.

These TMR-based sensors use a dual push-pull Wheatstone bridge configuration, and each sensor is loaded with four ultra-sensitive sensing elements. The whole framework is designed to enable accurate X and Y axis angle detection.

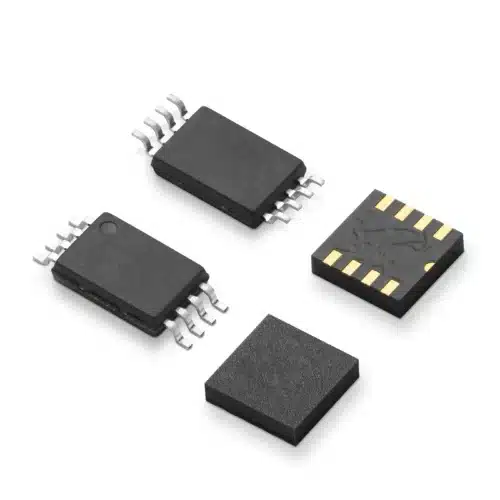

Covered over a robust TSSOP8 package, the LF53466 offers precision angle sensing, with less than 0.8° error across a 200 Gs-800 Gs magnetic field range. It has mechanical solder joints and steering wheel angle sensors, pedal position sensors, and contactless potentiometers, making inspection easy. The features make this variant ideal for industrial and automotive applications.

The LF53464 is available in a compact LGA8L package. It is made to angle error below 0.6°, while enabling wider airgap capability and compatibility with smaller, lower-cost magnets. This variant is made to be well-suited for applications that are space-restricted, like rotary encoders, knob and valve position sensing, and consumer devices, including power tools and appliances.

They are shipped in tape-and-reel packaging, 3,000 pieces per reel for the LF53466 and 4,000 pieces per reel for the LF53464. “These new TMR omnipolar sensors significantly expand the Littelfuse magnetic sensing portfolio by opening access to broader industrial, mobility, and consumer markets,” said Julius Venckus, Global Product Manager, Sensors. “The LF53466 and LF53464 enhance applications requiring speed control and precise angle detection by combining high accuracy, thermal resilience, and packaging flexibility,” he adds.