Robots built from 3D-printed blocks navigated outdoor obstacles, formed bridges, and worked with drones to assemble structures.

Researchers at Dartmouth College, working with Rutgers University and Yale University, have tested modular robots designed to assemble into different forms and operate outside controlled lab conditions. The study was published in Nature Communications.

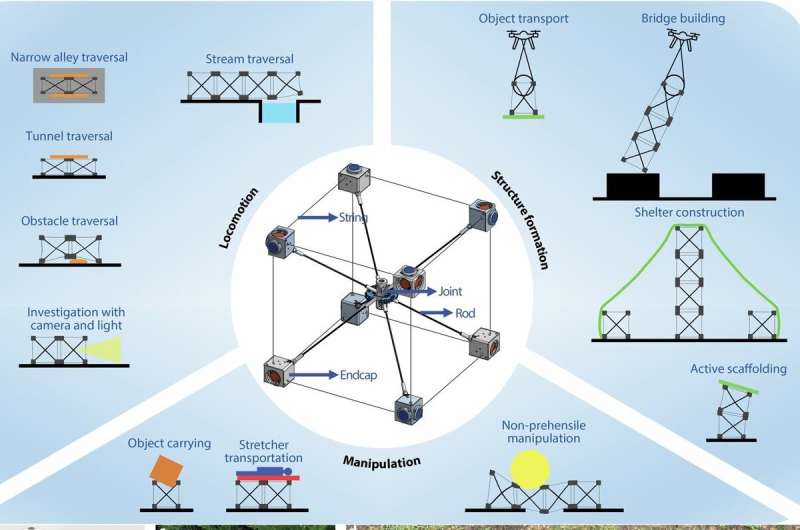

The robots are built from cube-shaped blocks. Each block has eight rods attached to a 3D-printed centre. The centre houses a battery and a Wi-Fi unit, which allows untethered communication and powers the robot for more than three hours. The rods are linked by strings whose tension is controlled by small motors. Adjusting the strings changes the shape of the block, allowing it to move. Latches on the rod end-caps let blocks connect to one another.

Field tests took place near the Dartmouth campus. The robots moved under fallen logs, passed through narrow gaps, and joined together to form scaffolds. Chains of connected modules created a bridge across a small brook and carried lightweight objects. A stretcher was formed by laying a board across linked blocks, which supported a human dummy. In another test, a drone located and retrieved a malfunctioning module.

The design was inspired by ants that link their bodies to form bridges. The researchers reported that small deformations in individual modules added up to significant collective movement and load-bearing ability when connected.

Drone deployment was also tested as a method to assemble taller structures. This allowed modules to be positioned above ground level, enabling 3D configurations.

According to the research team, potential applications include disaster response, temporary shelters, and equipment transport. Ongoing work aims to increase load capacity and autonomy, with sensors planned to allow robots to perceive and adapt to their environment.