Make-in-India is NOT assembled in India. Can the country shift from assembly lines to ownership of designs and products? Despite strong talent and policy support, India’s electronics sector is booming in scale but lacking in innovation. As the world realigns its supply chains, can we finally emerge as the global nerve centre of complex modern multinational supply chains, along with developing its edge in design and IP?

Table of Contents

Crisis often begets opportunities. From the US-China trade war to the pandemic, supply chain shocks and geopolitical tensions, the world’s overdependence on China has been exposed. The world is in pursuit of new business models. Global business dynamics are already undergoing a significant shift, as nations are now devising exit strategies from China and aiming to become more self-reliant.

India, a young nation renowned for its innovative spirit, can take the lead in shaping a new work culture. India, with the right blend of physical and virtual infrastructure and conducive government policies, can emerge as the global nerve centre of complex modern multinational supply chains. The recent Covid-19 crisis and changing geopolitical scenarios have presented India, and especially the ESDM (electronics system design and manufacturing) ecosystem, with an unexpected, longer-horizon opportunity to expand its manufacturing and R&D base and play a larger role in revamped global supply chains, spawned by the sudden but inevitable global rush to reduce economic dependence on China.

However, despite its global dominance in smartphone usage and 5G adoption, India still imports much of what it consumes. The real question is: can India move from being a consumer to a creator of intellectual property (IP), products, and global brands? The clock is ticking, say experts. Is India prepared to compete and fill the vacuum created by the world’s technological overdependence on our neighbour?

We have barely scratched the surface

Though relatively young, India’s ESDM industry has a long history. Initially dominated by public sector undertakings. The sector opened up post-liberalisation, with private Indian firms and global players entering the market. The first significant investments occurred between 2005 and 2007, when companies such as Nokia and Jabil Circuits established operations.

“I think the first time the term ESDM was coined was back in the 2008-09 time frame when, along with several other industry leaders, we were working on a recommendation for the government of India that subsequently, in 2011-12 time frame, resulted in the first national policy in electronics,” recollected Jaswinder Ahuja, ex-Corporate Vice President of Cadence Design Systems.

Despite a temporary slowdown in 2013-14, the sector rebounded, and today, India is a key global destination for electronics manufacturing. The sector operates through four primary business models. The most common is EMS (electronic manufacturing services), where original equipment manufacturers provide the design and ESDM firms handle the manufacturing. The ODM (original design manufacturing) model goes further, with ESDM firms managing everything from product design to development and production.

On the other hand, job work involves short-term, contract-based manufacturing or prototyping, often serving as an entry point for longer engagements. Lastly, after-sales services, including repair, refurbishment, and maintenance, are gaining importance as companies aim to enhance brand loyalty and address growing concerns around e-waste and product lifecycle support.

The industry currently comprises over 700 companies, including global giants (Bharat FIH, Wistron, and Pegatron), large Indian players (Dixon, Kaynes, and Syrma), and mid-sized firms (VVDN and Avalon). The market is dominated by mobile phones, consumer electronics, and industrial electronics, which collectively contribute over 75% of the total output. The fact is, EMS still accounts for 80% of the market, and ODM is still a growing segment—rather one that is yet to grow. The initial government push was towards manufacturing.

However, manufacturing without design would not be a good road map for long-term success. N. Kishor Narang, the founder of Narnix Technolabs, reminded us that we first made India the back office of the world by opening a multitude of BPOs, and by simply setting up an EMS plant without indigenous R&D for Chinese and global brands, we are turning India into the backyard factory of the world.

Citing global trends, Jaswinder added, “Nvidia has no manufacturing at all. It is all design; it is all intellectual property.” In the case of India, despite having “the largest workforce of designers,” the country lacks a true indigenous design ecosystem—most talent operates in global capability centres. It is a “huge vacuum” that must be addressed. Although there are schemes like ISM (India Semiconductor Mission), C2S (Chips to Startup), and DLI (Design-Linked Incentive Scheme), the offtake has been slow, which all the more requires private enterprise to step up. “The government can only do so much… private enterprise has to step forward,” stated Jaswinder.

A peep into India’s policy playbook, powering ESDM growth

Looking at how much the government has done, key efforts include the Production Linked Incentive (PLI) schemes, with ₹15.96 billion disbursed in H1 FY25 and targeted extensions to FY26, especially for electronics, IT hardware, and large-scale manufacturing. The highly commended ISM, with an initial ₹760 billion outlay, and the recent foundation of three semiconductor plants (₹1.25 trillion investment) highlight India’s focus on chip manufacturing.

According to the India Brand Equity Foundation (IBEF), partnerships, such as India-Taiwan talks and a proposed $7.5 billion fab facility, aim to boost chip production. Budget allocations for MeitY (Ministry of Electronics and Information Technology) have seen major increases too: ₹143 billion in FY23 and ₹165.49 billion in FY24.

The National Policy on Electronics 2019, along with programmes such as Make in India, Digital India, and Future Skills, emphasises workforce development, digital infrastructure, and indigenous innovation. Some recent specialised support includes the MeitY-Meta XR Accelerator, quantum computing labs with Amazon Web Services (AWS), and partnerships like the IIT Indore-CIMEI MoU.

Further, the Advanced Chemistry Cell (ACC) PLI (₹181 billion) supports battery manufacturing, while electronics research and development (R&D) is backed by a dedicated ₹320 million research fund.

Moreover, India’s ESDM sector has attracted `490.68 billion (US$5.67 billion) in FDI (2000-2024). Three years ago, a Frost & Sullivan report predicted that the ESDM market in the country would grow from ₹2.65 trillion (approximately US$36 billion) in FY21 to ₹9.96 trillion (approximately US$135 billion) by FY26. The share of Indian companies is expected to jump from ₹1.7 trillion (approximately US$14 billion) to ₹5.97 trillion (approximately US$81 billion), driven by design-led manufacturing, import substitution, and increasing demand for localised solutions.

As per a December 2024 report by The Economic Times, India’s ESDM industry, valued at ₹2.09 trillion in FY23, is projected to grow at a 34% compound annual growth rate (CAGR) to reach ₹9.09 trillion by FY28. A recalibration, not a slowdown, is needed, as earlier projections overshot near-term growth. But what is the contribution to this growth from the Indian perspective?

It must be noted that research and design are two different games altogether; the funding support in India is primarily allocated to research, and this support is typically given to academic institutions. And, somehow, it has never resulted in any product/system design and reached the Indian industries.

There is no comprehensive/structured funding scheme to promote product and systems designs that could be mass-manufactured by the Indian industrial ecosystem, be it for local consumption or the global market.

The constraints inhibiting innovation and design in India

With a population of 1.4 billion and a massive consumer base, the country presents a natural market for electronics. However, this potential remains largely untapped. “We have the market, we have the talent, so why cannot we do design, making all in India?” pointed out T.S. Shankar, currently the Sales Director at Analog Devices.

Government incentives like PLI and DLI exist, but struggle with execution and limited uptake. The design gap is glaring: while Indian engineers play a crucial role in global tech development, including quantum computing, domestic ownership of innovation remains minimal.

“You can manufacture 100,000 iPhones here, but the question is what is your contribution from the Indian perspective?” noted Shankar. Capturing the opportunity of a $500 billion electronics and services market by 2040 requires urgent alignment between policy, talent, and execution. “There is a window of opportunity. The question is if we can do that, and how?” he said.

This urgency was echoed by another industry veteran, Bhartendu Mishra, Managing Director-India at Arrow Electronics, who highlighted India’s fast-growing semiconductor consumption, at $41 billion annually, or 8% of global demand, as a signal that the country can no longer rely on being a consumption-led market. “What happened in the first 20 years doubled in the next eight and doubled again in the next five,” he said.

But growth without innovation is unsustainable. Despite producing $100 billion worth of electronics and exporting $29 billion, India still lacks global brands. “We killed our brands in the 90s. How do we bring them back?” he challenged, pointing to India’s 500,000 annual engineering graduates as a resource that must now be channelled into building for the world and India itself.

Kishor Narang responded with a harsh statement: that most of our engineers lack the competence to innovate and design. However, they are not to be blamed because our engineering institutes do not have faculty who can teach them design. They are very good at research, but they themselves have never done a single product design because that is all they have learnt. They have never worked in the industry designing end-to-end products and/or systems. They are not familiar with the compliance standards that the products must comply with before being supplied to any market.

Even software standards like MISRA C and ISO 26262 are not taught in any software courses. MISRA (Motor Industry Software Reliability Association) C is the safe coding standard, and the standard ISO 26262 is an adaptation of the functional safety standard IEC 61508 for automotive electric/electronic systems. ISO 26262 defines functional safety for automotive equipment applicable throughout the lifecycle of all automotive electronic and electrical safety-related systems.

He further emphasised the criticality of building indigenous design capabilities in the strategic electronics domain: defence and aerospace, due to changing geopolitical scenarios.

India has started making great strides in manufacturing, but how about designing?

While India’s electronics manufacturing capabilities have soared, expected to hit $150 billion this year, it can be unanimously agreed that manufacturing is necessary but not sufficient. According to Josh Foulger, president of the electronics division of ZETWERK, the next five years as EMS 2.0, with the government targeting $500 billion, can be a reasonable goal if everyone rows in the same direction. While many companies have proven the impact of government initiatives, there is an urgent need to shift from GCCs to true product innovation. Design hubs like Bengaluru must pivot from task-based execution to product ownership. “Qualify your product, validate it, and take it to mass production,” he urged.

And the biggest bottleneck? Components. India still imports critical components, such as PCBs and displays. Each component category requires its ecosystem. “We have checked the EMS 1.0 box. Now we have got to do India-plus-demand,” Josh said.

Millions of engineers, but where is the innovation?

The country has built factories, but what about the brains behind the products? Industry trailblazers often highlight a foundational issue: education. “We do not have an education system, we have an exam system,” stated Jaswinder. Bright engineering graduates from top schools often take two years to become productive. Engineering students are trained to pass tests, rather than to solve real-world problems or design products from end to end. Project-based learning can only be an alternative for big ESDM dreams.

“Our education system is more qualification-oriented than knowledge-oriented,” noted Kishor. Though many institutions claim to encourage projects, a reboot is needed of how college projects are conceived; students should be designing hardware, coding from scratch, and working on micro-drones, power electronics, and real-world applications.

While industry-university collaboration is improving through government-backed incubation programmes, the pace of change is painstakingly slow.

“The time it takes to bridge this gap is still too long. Engineers struggle to understand compliance, standards, and validation. They are taught how to build a product, but not how to make it usable at scale,” said Shankar.

Is India’s strength as a chip designer a flawed notion, then? Jaswinder challenged, “Most of our engineers are task executors, not true chip designers.”

Reclaiming India’s large pool of talent

India leads the world in smartwatch usage and 5G rollout, yet contributes little to their design or IP. While government initiatives, such as the National Skill Development Mission, have made strides in manufacturing, there is a deeper need to expand into electronics, product design, and innovation, particularly beyond urban hubs.

“We are converting our best engineers into bankers and managers,” Kishor pointed out, questioning the cultural norm of IIT students preparing for MBAs by their third year. “One seat in IIT was lost for innovation.”

Students often pursue engineering because the focus is on securing a job, rather than building products or pursuing entrepreneurship. What is needed is a shift from the mindset of a job seeker to a job giver. A system where they will not be afraid of raising their hands and asking questions in class, guided by teachers who foster curiosity.

At the same time, established companies must also be held accountable, particularly when it comes to inclusion and innovation. While government-backed incubators can support startups in their early stages, it is the responsibility of larger enterprises to step forward and invest in talent. As Bhartendu rightly asked, “If you are taking subsidies, are you hiring for innovation or importing tech and rebranding it?”

India’s future: from capable to world-class

“When I returned to India 20 years ago to start Nokia, we were terrified. But we went from zero to making seven phones a second, shipped to 110 countries, in just four years. At that time, Nokia’s local material costs were lower than those of China. So when someone says it cannot be done, I say, we have already done it,” narrated Josh, citing his personal experience.

However, China has surged ahead in design. From chipset to embedded software, everything is designed and built in-house. “That is the benchmark now,” he said. “Manufacturing is no longer enough. It is time for design to lead.”

India also faces a critical cultural point: the need to broaden participation and inclusion. “In our factory, 100% of the workforce was women. Maybe we need more women in hardware now,” Josh said. “Women made all the phones at Nokia and Foxconn. So why not have them lead in design too?”

Standing at an inflexion point, India’s ESDM sector has demonstrated its ability to manufacture at scale. Now, it must prove it can design with vision. The country’s future depends not just on building factories, but on building ecosystems that empower its millions of engineers to think independently, innovate fearlessly, and design proudly—for India and the world.

With tremendous engineering potential, India needs to remember what it is capable of. Like Hanuman from Ramayana was reminded by Jambavana, Josh put forward a powerful analogy from Indian mythology. The leap forward, as big as crossing oceans, will begin not with a new policy, but with the realisation that it can do far more than it believes. And the time to leap is now.

Kishor Narang concluded with some clear imperatives: If we want to build a vibrant innovation and design ecosystem in the long run, then we need to focus on first building “the competence to innovate and design” for the next five to ten years. Suppose India wants to be a serious player in this competition, while also fulfilling perennially urgent goals of boosting manufacturing and creating jobs. In that case, several fundamental changes in policy and mindset are necessary.

And for this, we have two crucial imperatives:

- Setting up a national institute of design and innovation in electronics, where the faculty shall not be merely academicians and researchers but rather practicing design engineers from respective domains in the industry.

- Establishing large, independent design houses with the capability to design end-to-end, high-end products ready for mass manufacture and transferring the complete know-how to Indian industries willing to take up manufacturing.

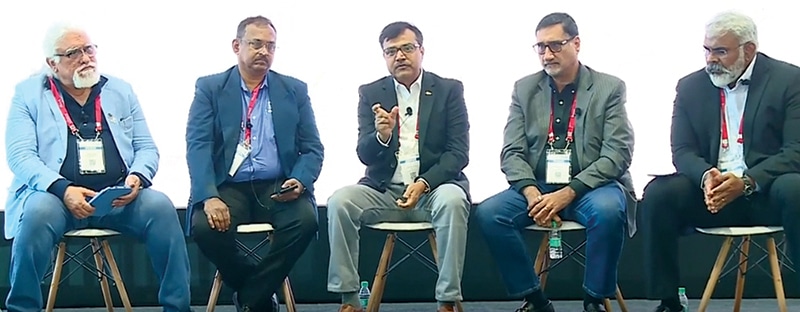

The article is based on insights from the panel discussion titled “Striding Towards Global Leadership in ESDM: Role and Strategies for India’s Ecosystem,” held on 28 February 2025 during the smartBHARAT summit at India Electronics Week in Bengaluru. It was moderated by N. Kishor Narang, Mentor and Principal Design Architect, Narnix Technolabs Pvt Ltd, with panellists Jaswinder Ahuja, ex-Corporate Vice President of Cadence Design Systems; Josh Foulger, President, Electronics, Zetwerk Manufacturing; T.S. Shankar, Sales Director, Analog Devices; and Bhartendu Mishra, Managing Director, Arrow Electronics, India.