Soochow University scientists have turned humble cotton yarn into high-performance methanol fuel cells that bend, flex, and even work when cut in half—offering a resilient, fast-refueling power source for next-gen wearables and smart textiles.

Cotton yarn could soon become the backbone of future wearable power systems. Researchers at Soochow University have developed fiber-shaped direct methanol fuel cells (FDMFCs) that maintain high performance even after being bent 2,000 times, cut in half, or soaked in water. The study, published in Nature Materials, marks a breakthrough in flexible energy storage, with implications for electronics that must bend, flex, and survive daily wear.

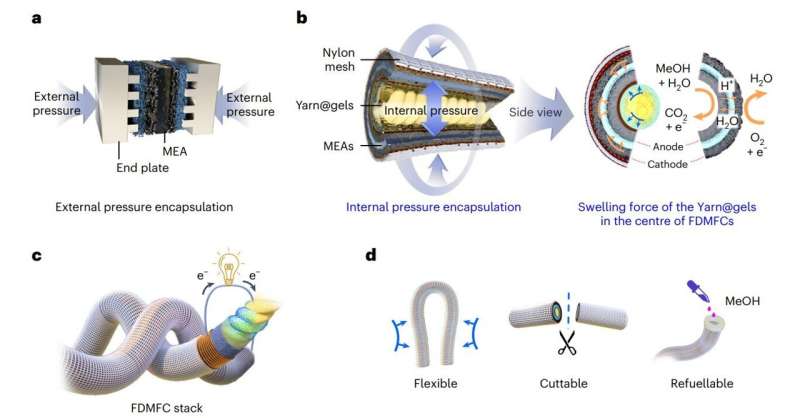

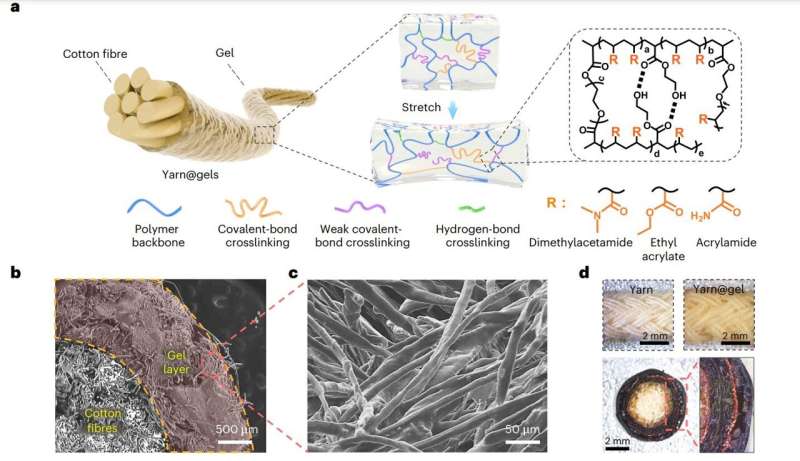

Unlike conventional batteries that rely on rigid housings, these cotton-based “Yarn@gels” create their own internal pressure. Cotton fibers naturally swell inside a gel matrix, pressing fuel cell components tightly together without the need for bulky casings. This adaptive pressure strategy allows the fuel cells to remain lightweight, cuttable, water-resistant, and fast to refuel—requiring only a minute to recharge.

For the growing wearable and smart textile industry, such resilience could be a game-changer. Flexible electronics—from bendable medical sensors to foldable consumer gadgets—require compact and durable energy sources. Existing solutions like solar cells and supercapacitors often fall short due to light dependence or slow recharge. Fuel cells, with their high energy density and rapid refueling, offer a compelling alternative—but until now, flexible versions struggled with leakage, sealing issues, and poor durability.

The team solved these challenges by embedding cotton yarn in a UV-cured gel, then layering catalyst-coated membranes around the fiber core. The result: fuel cells that maintained 94.7% of their power after 1,500 bends and continued functioning in extreme conditions ranging from −22 °C to 70 °C. They achieved peak power densities of 27.3 mW/cm² at 60 °C, with no voltage loss after 100 charge–discharge cycles.

Performance tests pushed the cells further—through water sprays, wooden stick penetrations, and repeated flex cycles—yet the devices kept working. Their modular, fiber-shaped design also suggests scalability, from powering smart clothing to larger energy systems. If adopted widely, cotton-based methanol fuel cells could usher in a new era of safe, flexible, and sustainable energy for the electronics industry—bringing the humble yarn into the spotlight of high-tech innovation.