A new chip-making technology can cut costs, increase speed, and let engineers change designs instantly. Learn how maskless lithography is changing semiconductor production.

Semiconductor manufacturers face rising costs and production challenges as demand grows for low-power, high-bandwidth components in AI, 5G, and data center applications. Photomasks used in lithography add cost, slow design changes, and limit scalability, making it harder to meet packaging requirements where multiple chips and technologies are combined into one system.

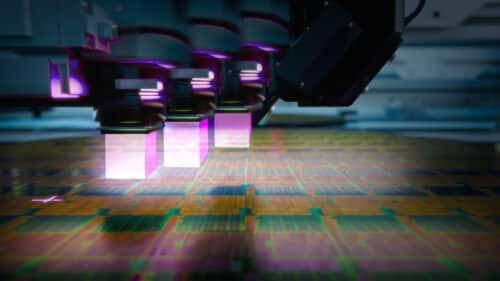

Texas Instruments has introduced the DLP991UUV digital micromirror device to address this. The device enables maskless digital lithography, acting as a programmable photomask that projects designs directly onto substrates with pixel-level accuracy. This removes the need for mask infrastructure, allows design adjustments in real time, and improves throughput, yield, and cost in semiconductor manufacturing.

The digital micromirror device provides 8.9 million pixels, sub-micron resolution, and processing speeds of 110 gigapixels per second. It delivers 22.5 W/cm² power at 405 nm, operates down to 343 nm, and has a mirror pitch of 5.4 µm. These features support sub-micron precision on substrates of any size, giving equipment makers scalability and flexibility for advanced packaging.

The device is part of the company’s direct imaging portfolio. DLP technology, based on millions of microscopic mirrors for display and light control, is also used in 4K projection, automotive lighting, and industrial machine vision. The device is aimed at semiconductor packaging, where cost reduction, design flexibility, and performance are needed.

Some of the key features of the device include:

- Resolution: more than 8.9 million pixels

- Processing speed: up to 110 gigapixels per second

- Power: 22.5 W/cm² at 405 nm

- Wavelength range: works down to 343 nm

- Mirror size: 5.4 µm pitch (smallest in the portfolio)

“Just as we redefined cinema by enabling the transition from film to digital projection, TI’s DLP technology is once again at the forefront of a major industry shift,” said Jeff Marsh, vice president and general manager of DLP technology at TI. “We’re enabling the creation of maskless digital lithography systems that empower engineers around the world to breakthrough the current limits of advanced packaging and bring powerful computing solutions to market.”