Tiny, adaptable robots now walk, swim, and collaborate across varied terrains thanks to a modular 3D-printed design, paving the way for versatile micro robotics in medicine, environmental monitoring, and beyond.

A new generation of 3D-printed microrobots is breaking ground in adaptability and functionality, promising to reshape how robotics can operate across diverse real-world environments. Developed by researchers at Seoul National University, these modular microrobots—each smaller than a centimeter—can walk on various surfaces, swim, and even collaborate in groups, offering a major leap toward general-purpose micro-scale robotics.

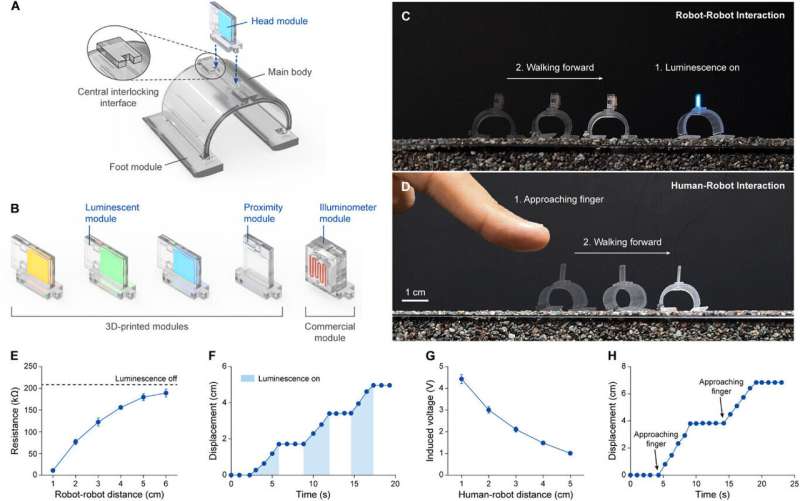

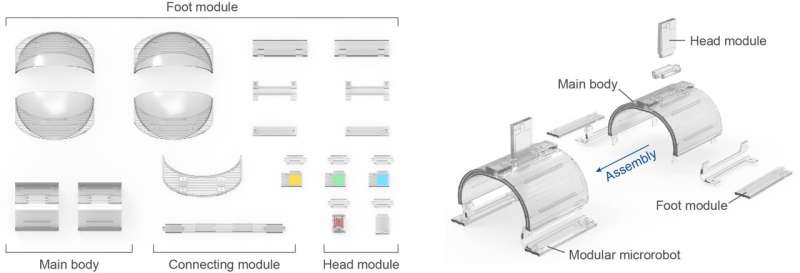

Unlike traditional microrobots, which are often purpose-built for narrow applications such as drug delivery or disease diagnostics, these new systems employ a modular architecture. This design allows researchers and engineers to swap components for different tasks, echoing the flexibility seen in drone technology. Each robot consists of a central body connected to interchangeable modules: legs for movement across flat, rough, or aquatic terrains; heads for real-time interaction; and connectors that allow multiple units to operate as one coordinated swarm.

The key advancement lies in fabrication. The team used a custom multi-material 3D printer capable of producing up to eight identical microrobot units per run, dramatically improving scalability and precision. This process not only speeds up production but also enables on-demand customization—modules can be printed or reconfigured for specific missions, from environmental monitoring to targeted biomedical operations.

In testing, the microrobots demonstrated robust locomotion across sand, water, and solid ground, maintaining stability and coordination even in challenging conditions. The researchers credit their modular design for this versatility, allowing the robots to mimic natural adaptability seen in insects while remaining highly controllable.

The implications stretch far beyond the lab. Modular microrobotics could eventually enable swarms of micro-machines to navigate confined or hazardous spaces, assist in minimally invasive surgery, or perform distributed sensing in environmental research. The 3D printing process also paves the way for affordable, large-scale production—an essential step toward commercialization.

By merging modular architecture with advanced 3D-printing materials, Seoul National University’s research signals a future where microrobots are not just tiny specialists but dynamic, general-purpose systems ready to operate in almost any environment.