The latest socket designs from Quasys make automated chip testing faster, safer, and more consistent.

As chips become smaller and more powerful, testing them for faults is becoming harder. In semiconductor factories, even a weak connection during testing can cause wrong readings or damage a chip. This makes it difficult to ensure every chip works as expected before it is used in real products.

Automated test equipment, or ATE, checks each chip’s electrical and functional performance. For this process to be accurate, the test system must connect properly with the chip. Test sockets and change kits are key parts that make this possible. They ensure steady contact between the device under test and the test system, allowing repeated, reliable measurements.

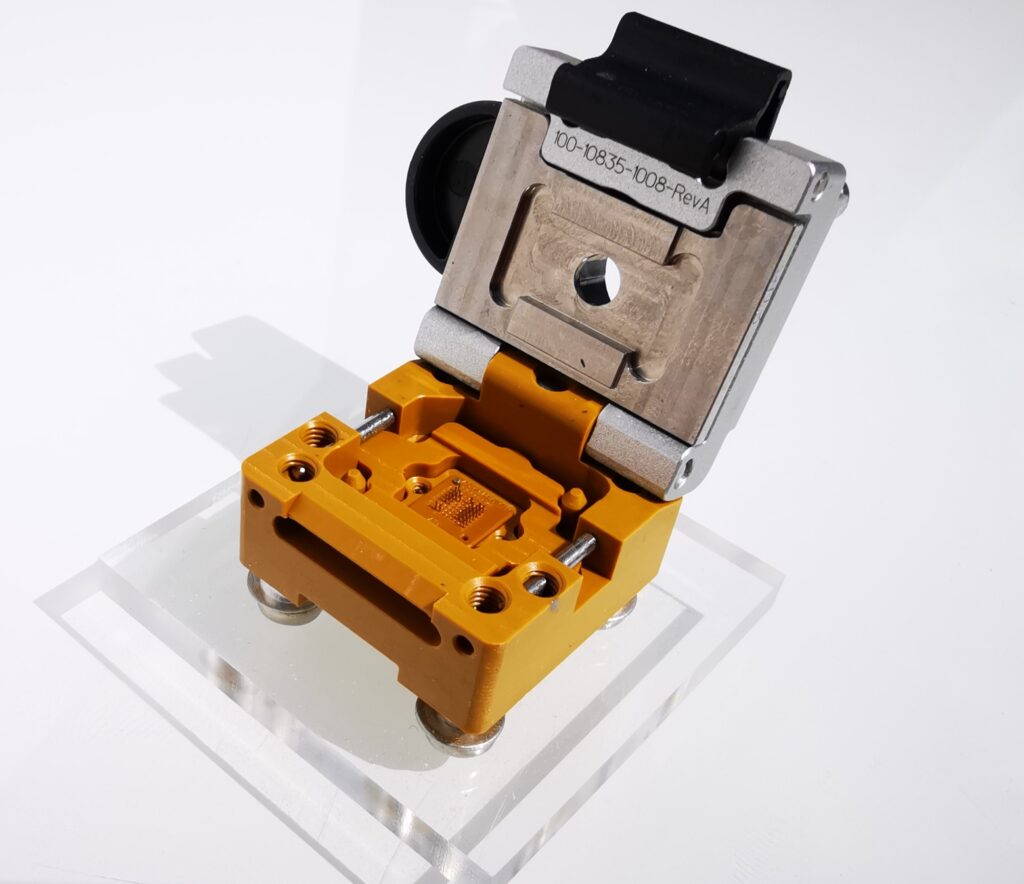

Quasys GmbH is showing its latest test sockets and change kits. These components are used in automated semiconductor testing to improve consistency and reduce test errors.

The test socket acts as the physical and electrical link to the chip. It holds the chip in place and ensures a stable current path during testing. Different socket types are used for different chip designs, such as BGA, QFN, and WLCSP. The contact elements, like spring pins or elastomers, helps prevent chip damage and electrostatic discharge while keeping measurements stable.

Temperature control is another challenge in chip testing. Many tests are carried out at very high or low temperatures to simulate how chips work in real-world conditions. Some sockets include active or passive cooling features to manage heat and ensure consistent test performance.

Signal quality also depends on the socket design. In high-frequency testing, even small signal losses can affect accuracy. Carefully designed sockets reduce crosstalk and signal distortion, helping test systems capture precise data.

Change kits complement the sockets by managing how each chip is picked, placed, and aligned automatically. Together, they improve test reliability and efficiency. As chip demand rises in sectors like AI, 5G, and electric vehicles, dependable testing systems remain vital to semiconductor manufacturing.