Delivering high power density, fast switching, and integrated control features, it provides a complete solution to evaluate and accelerate next-generation motor-drive designs.

As next-generation mechatronic systems demand smaller, lighter, and more energy-efficient actuators, this board offers a ready-to-use solution that demonstrates how gallium nitride (GaN) power technology can dramatically enhance performance. The EPC91118 reference design by Efficient Power Conversion Corporation (EPC) serves as a vital platform for engineers developing compact, high-efficiency motor drives across robotics, e-mobility, drones, and other motion-control applications Engineers can use this design to evaluate advanced motor control strategies, test inverter topologies, and explore thermal and power management techniques in systems requiring precise torque and speed control.

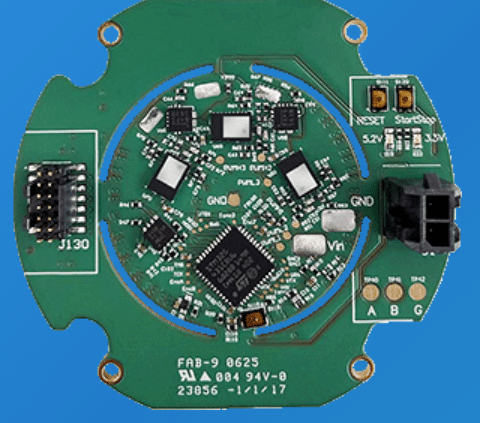

Its compact form factor makes it especially suited for integrated drive applications such as robotic joints, autonomous platforms, and electric propulsion systems where high power density and efficiency are critical. At the core of the EPC23104 ePower Stage IC, a 100 V, 15 A peak-rated device that integrates a high-performance GaN half-bridge and driver in a single package. This architecture significantly reduces parasitic losses and switching delays, enabling faster response times and improved energy conversion efficiency compared to traditional silicon-based solutions. The board delivers 10 A RMS continuous current and up to 15 A peak, allowing engineers to test realistic motor load conditions within a compact and thermally optimized setup.

With a DC input range of 15 V to 60 V, it accommodates a broad spectrum of brushless DC (BLDC) and permanent magnet synchronous motors (PMSM), making it ideal for evaluation in both low-voltage and mid-power systems. It is designed as a fully functional 3-phase inverter system, complete with all necessary control, sensing, and protection circuits. It features a microcontroller interface for motor control, precision current and voltage sensing for feedback, and integrated protection mechanisms to safeguard against overcurrent or thermal overloads.

It incorporates communication and programming interfaces such as RS485 and JTAG, providing flexibility for firmware development and real-time debugging. An onboard shaft angular sensor ensures accurate position feedback, supporting both open-loop and closed-loop motor control experiments.Engineers benefit from extensive design support materials provided by EPC, including a Quick-Start Guide, schematic diagrams, bill of materials, and Gerber layout files, enabling easy replication or customization. Complementary application notes and training videos further explain eGaN FET operation, assembly best practices, and design optimization techniques. EPC also offers simulation tools, a GaN selection guide, and a thermal calculator to streamline the design workflow.

For more information, click here.