TOPCon silicon solar cells achieve over 26% efficiency while significantly reducing silver usage and boosting bifacial performance showing how incremental manufacturing innovations can deliver both higher output and lower material costs at scale.

A research team led by the Ningbo Institute of Materials Technology and Engineering (NIMTE) has reported industrial-grade TOPCon silicon solar cells with a certified 26.09% power conversion efficiency (PCE) alongside lower silver consumption and improved bifacial performance, addressing key cost and material constraints in mainstream photovoltaics.

TOPCon (tunnel oxide passivating contact) technology already dominates the crystalline silicon market, capturing more than 70 % of global production due to its favorable efficiency and manufacturability. However, high silver paste usage, parasitic optical losses, and sub-optimal bifacial output have limited further performance gains and cost reductions at scale.

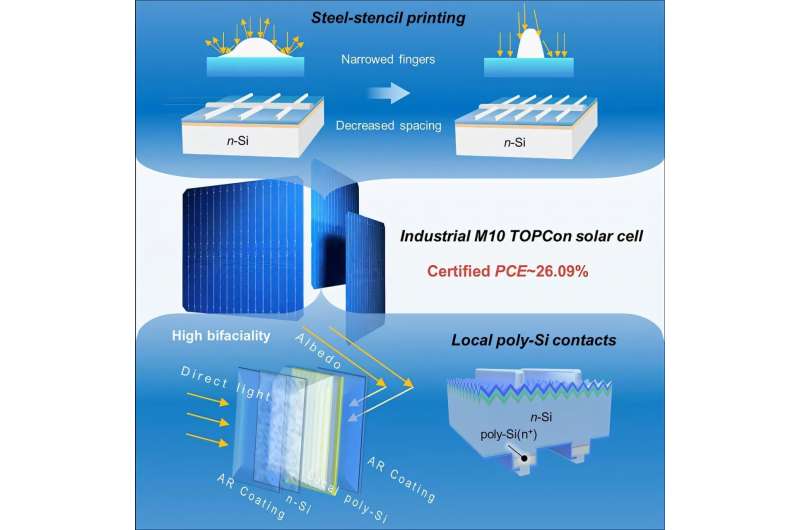

To tackle these challenges, the team developed a synergistic solution directly compatible with mass production processes. Key to the advance is a high-precision steel-stencil printing method that creates ultra-narrow front metal fingers on industrial M10 silicon wafers. This narrower grid reduces silver paste usage by about 0.12 mg per watt (mg/W) and, when paired with a tailored silver paste, promotes the formation of dense nanosilver clusters at the electrode–silicon interface. The result: better electrical contact and a lowered contact resistivity of 2.4 milliohm-cm².

On the rear side, the researchers redesigned the contacts with a localized polysilicon structure, reducing parasitic optical absorption and boosting bifaciality toward ~90 %a measure of how effectively a cell can harvest light from both front and back surfaces.

Taken together, these refinements allowed the team to overcome traditional trade-offs between efficiency, cost, and bifacial performance that have hindered industrial TOPCon improvements. Their results were published in Joule and open a pathway for producing high-efficiency, lower-cost TOPCon cells at industrial scales.

This advance aligns with broader industry efforts to curb silver demand and increasingly important factor as the PV sector scales. Recent research from other institutes has explored drastically reducing silver or replacing it with alternatives like copper to sustain large-scale photovoltaic deployment amid material and price pressures.