Check a whole bridge, plane, or machine for damage without touching it. A camera method turns video into virtual sensors, making monitoring faster and cheaper.

Structural health monitoring has a problem. Engineers need to see how structures move and wear over time, but the tools are expensive, limited, and hard to use on large structures. Contact sensors measure only small spots, cost a lot, and are hard to place in tricky areas, making monitoring slow and incomplete. Cameras can measure vibrations across whole structures without touching them, which is cheaper and covers more. But most camera methods fail in real situations because large movements, smooth surfaces, low texture, lighting changes, and noise reduce accuracy. Phase based optical flow improves this by using phase instead of raw pixels, but it still relies on pixels, making it sensitive to noise and hard to use for damage detection.

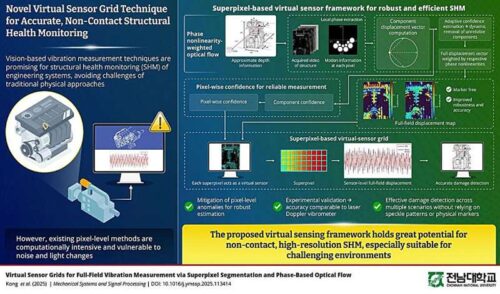

To address this, a research team at Chonnam National University in South Korea have developed a superpixel based virtual sensor method. The goal is simple. Turn pixel motion into sensor-like data that engineers can use.

Instead of treating each pixel as a measurement, the method groups nearby pixels that move in the same way into superpixels. Each superpixel acts as a virtual sensor. This reduces noise, improves stability, and creates a sensor grid that adapts to the shape and movement of the structure. No physical markers or contact sensors are needed.

The process works in three steps. First, motion is extracted from video using a phase based optical flow method. For each pixel, the method checks how reliable the motion is in different directions and removes weak data. This produces a full field displacement map without markers.

Second, a confidence value is calculated for each pixel motion. This reliability check is rare in vision based vibration methods and helps engineers know which data can be used.

Third, pixels are grouped into superpixels using displacement and confidence information. Depth data is added so the sensor grid aligns with the structure. Motion is then analyzed at the superpixel level, not the pixel level, making damage detection clearer.

When tested on an air compressor system, the method reached accuracy close to a laser Doppler vibrometer. While pixels showed variation, the superpixel sensors reduced this and made damage easier to detect, all without physical sensors or markers.

In practice, this approach solves a problem for engineers. How to get full field vibration data at low cost and with minimal setup. It is suited for infrastructure monitoring, aerospace structures, industrial equipment, robotics, smart cities, and digital twins. Anywhere engineers need non contact structural monitoring that works outside the lab.