A new ultraviolet laser source pushes maskless lithography closer to mainstream use in advanced semiconductor packaging by combining short wavelength, watt-class output, and long operational life in a compact form factor.

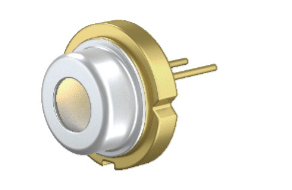

A high-power ultraviolet semiconductor laser by Nuvoton Technology entering mass production could significantly improve fine patterning and throughput in maskless lithography systems used for advanced semiconductor packaging. Emitting at 379 nm with a continuous-wave output of 1.0 W, the device delivers one of the highest power levels available at this wavelength in a compact TO-9 CAN package, addressing long-standing limitations of ultraviolet laser sources.

The laser is positioned as a key light source for maskless lithography, a technique gaining traction as advanced packaging architectures such as chiplets and 3D stacking become central to meeting AI-driven performance demands. Unlike conventional photomask-based exposure using mercury lamps, maskless lithography directly writes wiring patterns from design data. This approach reduces mask fabrication time and cost, simplifies alignment, and allows exposure on uneven or complex surfaces common in advanced packages.

The key features are:

- 379 nm ultraviolet emission near i-line wavelengths

- 1.0 W continuous-wave optical output

- Enhanced wall-plug efficiency device structure

- High thermal dissipation CAN package

- Designed for mercury lamp replacement

Achieving high output at short ultraviolet wavelengths has historically been difficult due to low wall-plug efficiency and severe heat generation, both of which accelerate device degradation. The new laser addresses these issues through a combination of optimized device structure and improved thermal management. A proprietary doping profile reduces optical absorption and operating voltage, enabling more efficient electrical-to-optical energy conversion. At the package level, high thermal conductivity materials and reduced thermal resistance help suppress temperature rise during high-power operation.

By stabilizing operation at the 1.0 W class, the laser supports finer line widths and higher exposure speeds, directly translating into improved throughput for lithography equipment. The extended operational lifetime also helps reduce downtime and maintenance costs for optical systems, an important consideration for high-volume manufacturing environments.

Beyond lithography, the ultraviolet laser broadens the range of solid-state alternatives to mercury lamps, supporting applications such as resin curing, precision marking, additive manufacturing, and biomedical instrumentation. As regulatory and environmental pressures continue to limit mercury use, semiconductor laser-based light sources are increasingly attractive for system designers seeking compact, efficient, and flexible solutions.

Overall, the launch signals a step forward for ultraviolet laser technology, aligning short-wavelength performance with practical manufacturing requirements in next-generation semiconductor packaging and related industrial applications.