Steam drives industry, but fossil boilers drive emissions. Modular electric heat pumps are emerging as a practical path to decarbonization.

As industries pursue decarbonization, steam generation remains one of the most difficult challenges to address due to its deep integration into manufacturing processes. Conventional steam boilers powered by fossil fuels continue to dominate industrial heat applications, contributing significantly to global emissions while offering limited pathways for electrification without operational disruption.

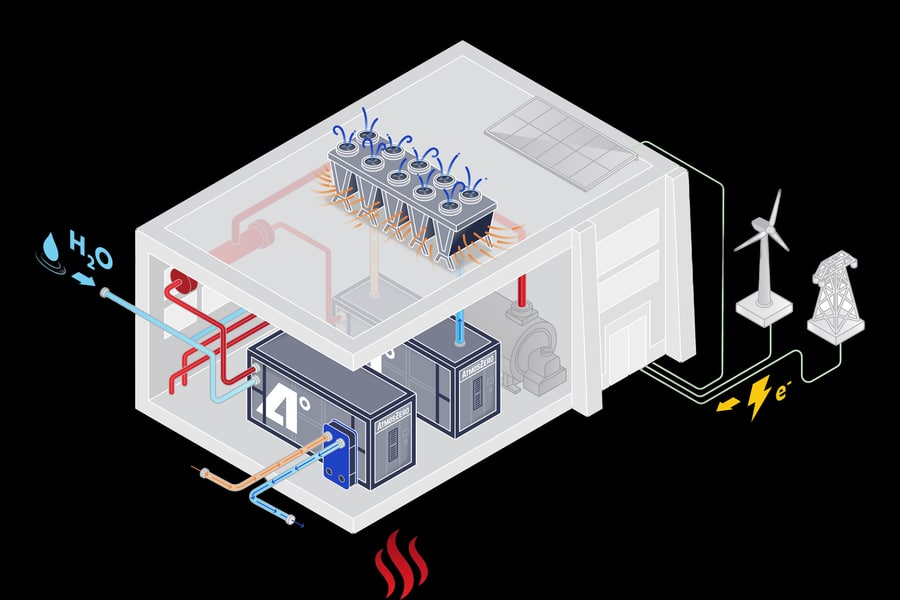

AtmosZero, a technology startup co-founded by MIT alumni, is addressing this challenge with a modular electric heat pump system designed to electrify industrial steam boilers. The system delivers high temperature steam up to 150°C and is engineered as a direct replacement for combustion based boilers used in sectors such as chemicals, food processing, pharmaceuticals, and paper manufacturing.

The company’s first one MW steam system leverages advanced compressor architecture to achieve high efficiency, consuming approximately 50% less electricity than conventional electric resistive boilers. Unlike many existing electric solutions, the system operates independently of industrial waste heat, simplifying deployment and reducing installation complexity. The modular architecture allows rapid on site installation, often within hours, with full deployment completed in days and no production downtime.

Key features of the development include:

- Modular electric heat pump delivering industrial steam up to 150°C

- Advanced compressor technology reducing electricity consumption by around 50%

- No dependency on industrial waste heat

- Drop in replacement compatible with existing steam infrastructure

- Rapid installation with zero production downtime

- Scalable platform for facilities below 10 MW thermal demand

Addison Stark, CEO of the company, adds, “Steam remains fundamental to industrial production. Delivering low emissions steam at scale requires solutions that combine efficiency, flexibility and ease of integration.”