Here is the list of India’s leading suppliers of Reflow Oven machines.

A & A GLOBAL RESOURCES PVT LTD

Website: www.smt-india.com

Address: No. 327, Siddharth Tower, 12/3B, Kothrud, Pune,

Maharashtra – 411038

Email: [email protected]

Contact: 9823141496

Inline Reflow Oven Brand(s) Supplied: TWS, Agate

Benchtop Reflow Oven Brand(s) Supplied: TWS, Agate

10 Leading Global OEMs

| BTU International Website: www.btu.com HQ: USA Heller Industries Website: www.hellerindustries.com HQ: USA Jaguar Automation Website: www.jaguar-ele.com HQ: China KAIT Website: www.kait-smt.com HQ: China Kurtz Ersa Website: www.kurtzersa.com HQ: Germany NeoDen Website: www.neodentech.com HQ: China REHM Thermal Systems Website: www.rehm-group.com HQ: Germany TAMURA CORPORATION Website: www.tamuracorp.com HQ: Japan TSM (HANWHA) Website: www.tsms.kr HQ: South Korea Vitronics Soltec Website: www.itweae.com/products/vitronics-soltec HQ: USA |

ACCUREX SOLUTIONS PVT LTD

Website: www.accurexsolutions.com

Address: #782, 3rd Main, 1 Cross, BEML Layout, 5th Stage, Rajarajeswari Nagar, Bengaluru – 560098 India

Email: [email protected]

Contact: 080-28611871

Inline Reflow Oven Brand(s) Supplied: JT Automation, SMT Germany

ACD RENAISSANCE LLP

Website: acd-renaissance.com

Address: E-303, Spring Meadows, Ambegaon Bk, Pune, Maharashtra – 411046

Email: [email protected]

Contact: 8411935923

Inline Reflow Oven Brand(s) Supplied: JT Automation

ALN TRONICS PVT LTD

Website: www.alntronics.com

Address: 11, Sampigehalli Main Road, Agrahara Village, Kogilu, Yelahanka, Bengaluru – 560064, Karnataka, India

Email: [email protected]

Contact: 9945274752

Inline Reflow Oven Brand(s) Supplied: Kurtz Ersa

AMERICAN TEC INDIA PVT LTD

Website: www.americantec.com

Address: FF-41, Omaxe Square, Jasola,

New Delhi South-East Delhi 110026

Email: [email protected]

Contact: 8923459870

Inline Reflow Oven Brand(s) Supplied: Heller, HB Technology, Rehm

ANTRIX AUTOMATION PVT LTD

Website: antrixonline.com

Address: 328, Vipul Business Park, Sector 48, Sohna Road, Gurugram – 122018, Haryana, India

Email: [email protected]

Contact: 98186 63818

Inline Reflow Oven Brand(s) Supplied: HB Technology

AXIS AUTOMATION

Website: www.axisautomation.in

Address: 857, Anagha Building, ACES Layout, 1st Main, B Block, Singasandra, Bengaluru, Karnataka – 560068

Email: [email protected]

Contact: 080 49529793

Inline Reflow Oven Brand(s) Supplied: Excelsius, HB Technology, Faroad

BERGEN ASSOCIATES PVT LTD

Website: bergengroupindia.com

Address: 305-306, Magnum House-1, Commercial Complex, Karampura,

Delhi – 110015

Email: [email protected]

Contact: 0124-6925600

Inline Reflow Oven Brand(s) Supplied: Kurtz Ersa

Indian OEMs

| ORGANISATION | Website |

| EMS TECHNOLOGIES PVT LTD | www.emstonline.com |

| EPS WORLDWIDE PVT LTD | www.eps-ww.com |

| XALTEN SYSTEMS PVT LTD | www.xaltensystems.com |

BERGEN SYSTEMS PVT LTD

Website: bergen-systems.com

Address: 409, Sector – 8 IMT Manesar, Gurugram,

Haryana -122050

Email: [email protected]

Contact: 0124 4599124

Inline Reflow Oven Brand(s) Supplied: TSM

Global OEMs In India

| Organisation | Website |

| HELLER THERMAL SYSTEMS | hellerindustries.in |

| KURTZ ERSA INDIA – SMART PRODUCTION TECHNOLOGIES PRIVATE LIMITED | kurtzersa.com |

EMS TECHNOLOGIES PVT LTD

Website: www.emstonline.com

Address: Gat No.322, Plot No.1, Vishwachaya Indistrial Estate, At Post- Pirangut, Taluka Mulshi, Dist. Pune 412115

Email: [email protected]

Contact: 7306907178

Inline Reflow Oven Brand(s) Supplied: EMS Technology

EPS WORLDWIDE PVT LTD

Website: www.eps-ww.com

Address: 145 Garmal, Dhayari, Pune, Maharashtra 411041, India

Email: [email protected]

Contact: 020-24392715

Inline Reflow Oven Brand(s) Supplied: EPS Worldwide

ETA INTERNATIONAL PTE LTD

Website: www.etasmt.com.sg

Address: 1742, 1st Floor, Sector 46, Gurugram 122003, Haryana

Email: [email protected]

Contact number:9920368386

Inline Reflow Oven Brand(s) Supplied: I.C.T.

HANWHA SEMITECH CO., LTD

Website: www.hanwha-pm.com

Address: 505, 5th Floor, Caddie Commercial Tower, Aerocity, New Delhi, India

Email: [email protected]

Contact: 981000134

Inline Reflow Oven Brand(s) Supplied: TSM

HELLER THERMAL SYSTEMS

Website: hellerindustries.in

Address: Block No. 97, Opp. Khodiyar Temple, Plot No. 24 And 25, Chacharwadi Vasna, Sanand, Ahmedabad – 382213

Email: [email protected]

Contact: 9845538474

Inline Reflow Oven Brand(s) Supplied: Heller

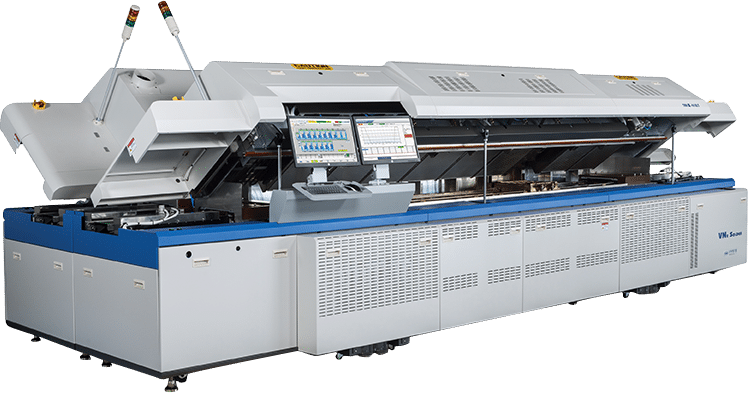

Types of Reflow Oven

| Reflow Oven Type | Key Characteristics | Best Suited Job Types | Typical EMS Use Case |

| Batch Reflow Oven | Non-inline, small footprint, lower cost | Prototyping, NPI, R&D, very low volume | Design validation, pilot runs, labs |

| Inline Convection Reflow (Air) | Forced hot air heating, stable and repeatable | Low to medium complexity assemblies | Consumer electronics, general industrial |

| Inline Convection Reflow (Nitrogen) | Inert atmosphere, reduced oxidation and voids | High-reliability, fine-pitch components | Automotive, EV, medical, aerospace |

| IR+Convection Reflow | IR assists convection, faster heating | Mixed assemblies, cost-sensitive lines | Tier-2/Tier-3 EMS, legacy lines |

| High-Zone Inline Reflow (10-12 zones) | Better thermal control, high uniformity | High-density, high thermal mass PCBs | Automotive ECUs, power electronics |

| Vapour Phase Reflow | Uniform boiling heat transfer, no overheating | Very complex, heavy boards, low defect tolerance | Specialised automotive, defense, R&D |

Key Advancement in Reflow Ovens

| Technology/Feature | What It Is/How It Works | Key Benefits for EMS Industry |

| Multi-Zone Thermal Control | Independent heating/cooling zones (>6-8+) to shape thermal profiles for preheat, soak, reflow, and cooling stages | Tighter temperature uniformityhigher yield and reliability, especially for lead-free and high-density boards |

| Advanced Temperature Profiling | Enhanced control algorithms and sensors that maintain temperature accuracy across zones | Lower defects, consistent solder joint quality, better handling of different paste alloys |

| Real-Time Monitoring and Feedback | Continuous tracking of thermal parameters with alarms and automated process adjustments | Detects process drift earlyreduces rework and improves SPC (statistical process control) |

| IoT and Digital Connectivity | Integration with MES/ERP, cloud dashboards, remote monitoring, and data logging | Greater traceability, remote troubleshooting, supports Industry 4.0 smart factories |

| Predictive Maintenance and AI | ML models analyse historical process data to forecast maintenance needs | Reduces unexpected downtime and extends equipment life |

| Nitrogen and Vacuum Atmospheres | Controlled gas chambers (nitrogen or vacuum) to reduce oxidation and voids | Better solder joint reliability—especially for automotive/medical electronics |

| Energy Efficiency and Heat Recovery | Systems that reuse waste heat and optimise heating to reduce power consumption | Lower energy costs and environmental impact |

| Compact and Modular Configurations | Benchtop and modular ovens scalable to production needs | Flexibility for small batches and SME/low-volume EMS environments |

| Automation and Conveyor Enhancements | Improved conveyors with tighter control and integration with material handling systems | Higher throughput, reduced board stress, smoother line flow |

| User-Friendly HMI and Recipe Management | Advanced touchscreens, recipe libraries, and guided setups | Shorter setup times, fewer operator errors, faster changeovers |

| Flux Management | Trap the flux residues inside the reflow by an advanced mechanism | Cleaner PCBA, more machine availability for production due to less cleaning of the Oven |

| Forced Cooling Through Chilled Water | Flow of chilled water in the heat exchangers in the cooling zones cools down the Nitrogen through convection and hence the PCBA temperature | Forced cooling in the first cooling zone is most important to control the duration of TAL. Cooling in subsequent cooling zones helps in reducing PCBA temperature. Lower PCBA temperature reduces false calls in post-reflow AOI |

IMTRONICS TECHNOLOGY