- Achieves better performance and provides high reliability in small size

- Allows simplification of soldering process for increase in production process

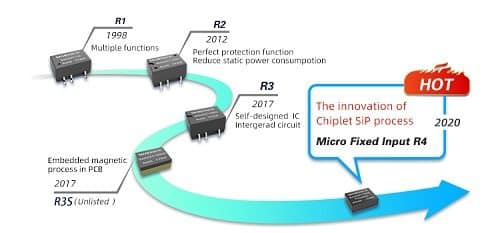

Based on end-use industry, such as portable equipment and IoT, DC-DC converters are expected to offer benefits in size, performance, reliability and cost. Therefore, MORNSUN has now released a new generation of fixed input R4 series by adopting the newest Chiplet SiP (System in Package) technology to achieve a reduction in dimensions by up to 80 per cent and thus save cost for the customer.

Based on end-use industry, such as portable equipment and IoT, DC-DC converters are expected to offer benefits in size, performance, reliability and cost. Therefore, MORNSUN has now released a new generation of fixed input R4 series by adopting the newest Chiplet SiP (System in Package) technology to achieve a reduction in dimensions by up to 80 per cent and thus save cost for the customer.

Here is a brief history of MORNSUN fixed input family.

Eliminating dimension restraints using Chiplet SiP

In order to achieve miniaturization of the power supply module, the concepts of both “embedded magnetic process in PCB” and “Chiplet SiP technology” were taken into consideration while developing the R4 generation. But after numerous reliability tests and verifications in some extreme application environments, it was found that the “embedded magnetic process in PCB” had long-term reliability risk. To overcome this drawback, the Chiplet SiP technology was adopted to design the new generation of fixed input R4 series as it not only solves the miniaturization but also achieves better performance.

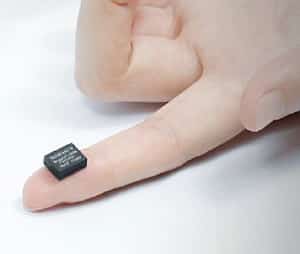

The dimensions of R4 has been reduced by 80 per cent and its layout space (LxW) has also been reduced by more than 50 per cent. The R4 generation is a comprehensive decoupling of the constraints among dimensions, appearance, surface mount packaging, high performance and high reliability as it integrates circuit technology, process technology and material technology.

Allowing ease of PCB soldering

More than 90 per cent of the components on the PCB is assembled by SMD reflow soldering. Some fixed input products with SIP package also need to be installed on PCB boards by wave soldering. This not only complicates customer product manufacturing process (including the SMD reflow soldering process and wave soldering process) but also increases the lead time, manufacturing costs and the risk of quality. However, the R4 generation can be mounted on PCB through SMD reflow soldering without extra wave soldering process, which simplifies the production process and reduces the production costs.

Further features

- 3.1mm thickness

- Micro-SMD package

- Meets AEC-Q100

- Operating temperature range: -40 degrees Celsius to 125 degrees Celsius

- ESD meets 8KV level (Contact)

- Static power consumption:35mW

- Continuous short-circuit protection

- Capacitive load:2400uF

- Isolation capacitance: 8pF

- I/O isolation test voltage: 3000 VDC

Through insights into industry trends and in-depth understanding of the market, MORNSUN is committed to technological innovation, product upgrades and best customers experience by developing more new products with good quality to meet industry applications and customers’ high requirements.