High-voltage circuits just got easier. See how new rectifiers cut power loss, save space, and improve reliability in industrial and automotive systems.

Design engineers in industrial and automotive electronics often work to balance efficiency, reliability, and design in high voltage circuits. Vishay’s Gen 7 platform of 1200 V FRED Pt Hyperfast rectifiers in the eSMP SlimSMA HV package addresses these challenges. The 1 A and 2 A devices provide a trade-off between reverse recovery charge (Qrr) and forward voltage drop while giving low junction capacitance and recovery time.

The rectifiers, VS-E7JX0112-M3, VS-E7JX0212-M3, and the AEC-Q101 qualified VS-E7JX0112HM3, VS-E7JX0212HM3, have recovery times down to 45 ns with Qrr as low as 105 nC, forward voltage drop of 1.45 V, and junction capacitance of 2.5 pF. These values reduce switching losses, lower power dissipation, and improve system efficiency.

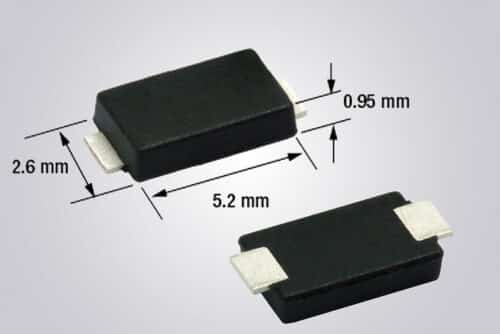

With a package measuring 2.6 mm by 5.2 mm and a 0.95 mm profile, the rectifiers fit layouts while maintaining a 3.2 mm minimum creepage distance. The molding compound has a comparative tracking index (CTI) ≥ 600 (Material Group I), supporting IEC 60664 1 compliance for high voltage applications. This helps engineers reduce component counts and lower BOM costs.

The devices can be used as clamp, snubber, and freewheeling diodes in flyback auxiliary power supplies, high frequency rectifiers for bootstrap drivers, and desaturation protection for switching IGBTs and high voltage Si/SiC MOSFETs. Applications include industrial drives and tools, EV on board chargers and motors, energy generation and storage systems, and Ćuk converters or industrial LED SEPIC circuits.

Built with a planar structure and platinum doped lifetime control, the rectifiers deliver system reliability without affecting performance. Stored charge and recovery currents reduce switching losses and power dissipation. The devices are RoHS compliant, halogen free, have a Moisture Sensitivity Level of 1 per J-STD-020, and support temperature operation up to +175 °C.

These rectifiers can be developed and implemented by electronics design engineers and system integrators working on high voltage industrial or automotive applications. Engineers with experience in power electronics, EV systems, energy storage, or LED driver design can use these devices to improve efficiency, reduce component count, and simplify thermal management in circuits.