The new materials and tools help electronics stay cool, work, and last, even in high power or hot conditions.

When electronic devices overheat, they can slow down, stop working, or even fail completely. This heat mainly comes from energy lost as electrons move through materials—similar to how friction generates heat in machines. Traditionally, silicon (Si) has been the main semiconductor used in these devices. But engineers are now turning to newer materials like gallium nitride (GaN), which can perform better and last longer. GaN is already found in LEDs, compact laptop chargers, and 5G systems.

For more demanding applications—such as high-voltage environments or extreme temperatures—researchers are exploring ultra-wide-bandgap (UWBG) materials like gallium oxide (Ga₂O₃), aluminum gallium nitride (AlGaN), and even diamond. These materials differ from others in their “bandgap,” the energy required to move electrons through them. A wider bandgap allows them to handle higher power, operate more efficiently, and enable smaller, more compact devices. Some UWBG materials can withstand electric fields up to 8,000 volts and continue to work beyond 200 °C, making them suitable for future systems in energy, healthcare, and communication.

However, UWBG semiconductors also come with challenges. They are expensive, hard to manufacture, and difficult to test for heat buildup. As transistors shrink and more power is packed into smaller areas, heat can accumulate in tiny zones—sometimes reaching energy flux levels higher than the surface of the sun. This creates a strong need for new tools that can accurately measure temperature at microscopic scales.

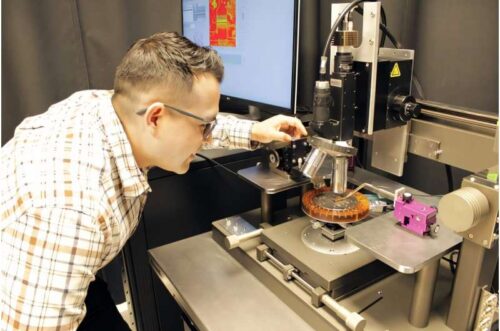

To address this, researchers are developing advanced thermal metrology techniques. Optical methods like Raman spectroscopy and thermoreflectance use light to detect temperature. Electrical techniques infer heat from changes in voltage or resistance. Scanning-probe methods—such as scanning thermal microscopy—physically touch the surface to find hot spots. Hybrid approaches are also emerging. These include combining multicolor thermal imaging to visualize nitride devices, tracking defect-related absorption in gallium oxide components, and using deep-ultraviolet microscopes to map heat patterns smaller than a micrometer.

Together, these new materials and thermal tools offer a path to smaller, more efficient, and more reliable electronics. They help extend device lifetimes, reduce energy waste, and enable better performance in harsh conditions—paving the way for advances across multiple industries.