The method extracts lithium from rock in minutes using low heat and water, without acid and with less energy than traditional processes.

Lightweight yet essential, lithium metal is a critical mineral at the heart of rechargeable batteries that power smartphones, laptops, electric vehicles, and more. Despite its widespread use in modern technology, lithium extraction remains a complex and costly process. Researchers at Penn State have developed a newly patented method that dramatically improves efficiency—extracting lithium in minutes rather than hours—by using low-temperature, water-based leaching techniques.

Extracting lithium directly from mined rock is faster, but it requires extreme heat—up to 1,110 degrees Celsius sustained for about two hours. This high-temperature treatment makes the mineral structure porous, allowing the lithium to be separated from the surrounding rock.

Next, the porous mineral undergoes sulfuric acid baking, a process in which it is treated with sulfuric acid and heated to 482 degrees Fahrenheit for two hours. This step dissolves much of the lithium into an acidic solution, which is then neutralized and processed further to purify the extracted metal.

When the research team began exploring ways to improve the lithium extraction process, they identified an opportunity to eliminate the need for phase transformation—the intense heating and sulfuric acid baking traditionally used to release lithium ions from the mineral structure.

The researchers also explored the use of microwave heating—much like using a microwave instead of a conventional oven—to accelerate the low-temperature reaction, reducing processing time to just minutes.

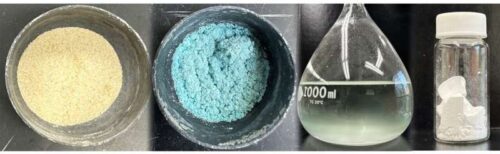

This method produces lithium sodium silicate, a compound that dissolves easily in water at room temperature. When water is added, the lithium leaches out in about a minute. Because the solution is already basic rather than acidic, it eliminates the need for additional chemicals typically required in conventional methods to neutralize acidity. A solidifying agent can then be added immediately to isolate and collect the lithium.

The process is also effective for extracting other critical minerals, including rubidium and cesium—used in electronics, quantum computing, solar panels, atomic clocks, satellite navigation, batteries, and rocket propellants—from lepidolite, a lithium-bearing rock. It can similarly extract lithium from clay-based sources.

Reference: H.C.S. Subasinghe et al, Direct lithium extraction from α-Spodumene using NaOH roasting and water leaching, Chemical Engineering Journal (2025). DOI: 10.1016/j.cej.2025.159661, www.sciencedirect.com/science/ … 1385894725004607?via%3Dihub