A team at Denmark’s Technical University has engineered an electronic material that mimics human skin—flexible, stretchable, and capable of healing itself in seconds, this innovation could reshape the future of healthcare wearables, soft robotics, and implantable devices.

Researchers at the Technical University of Denmark (DTU) have created a new electronic material that closely mimics the properties of human skin. This flexible, stretchable, and self-repairing substance is poised to revolutionize fields like soft robotics, wearable electronics, and medical technology.

The innovation stems from the fusion of two advanced materials—graphene and PEDOT:PSS. Graphene, a form of carbon known for its exceptional strength and conductivity, is combined with PEDOT:PSS, a transparent and conductive polymer commonly used in flexible electronics. The result is a material that not only conducts electricity efficiently but is also durable, stretchable, and capable of healing itself after damage—much like human skin.

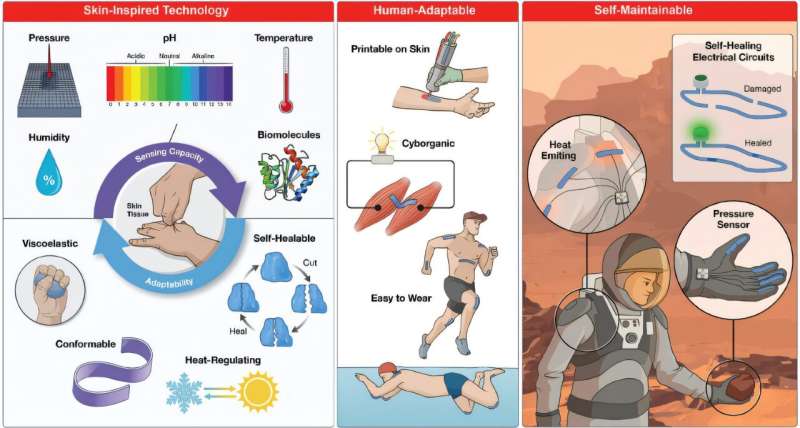

“Our aim was to create a multifunctional material that integrates softness, sensitivity, and self-healing—all in one platform,” said Associate Professor Alireza Dolatshahi-Pirouz from DTU Health Tech. This development could pave the way for more natural interactions between humans and electronic systems. What makes the material stand out is its ability to recover within seconds after damage. It can be stretched up to six times its length and still return to its original shape, making it ideal for wearable devices and robotic applications that undergo constant movement and bending. Additionally, it can sense environmental conditions such as pressure, temperature, and pH levels—capabilities crucial for real-time health monitoring systems.

The researchers envision multiple real-world applications: smart bandages that monitor wound healing, skin-like sensors for prosthetics, or surgical tools for minimally invasive procedures. It could even find use in space technology or implantable medical devices due to its adaptability and biocompatibility. Currently, the DTU team is focused on scaling up production methods to transition from laboratory innovation to practical implementation. If successful, this material could become a cornerstone of next-generation electronic devices that are as resilient and adaptive as the human body itself.