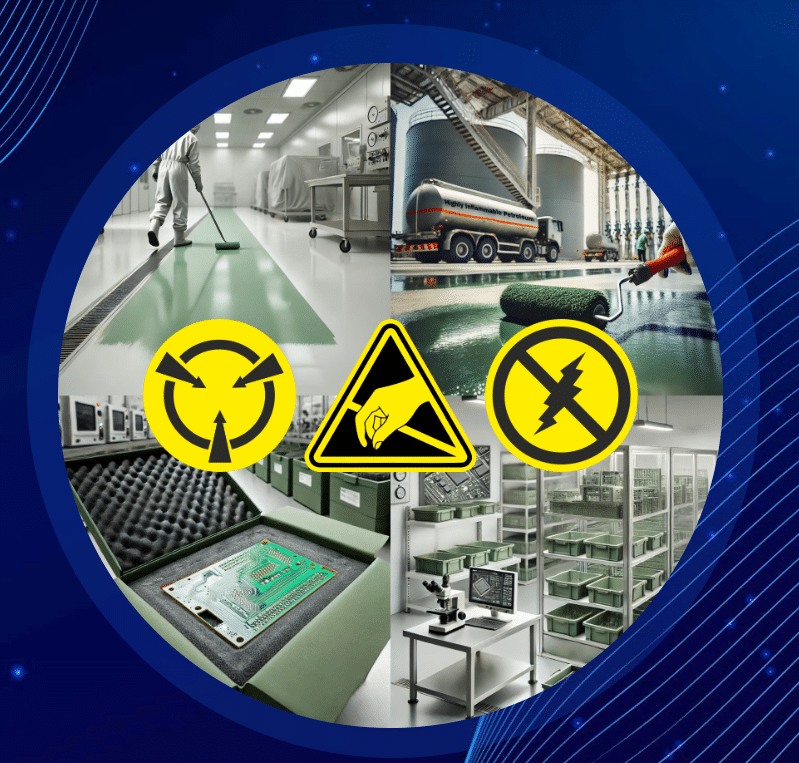

With ready-to-use application, universal surface compatibility, and zero maintenance, it sets a new standard for long-term, eco-friendly ESD safety across electronics, defense, and cleanroom industries.

ProShield, SCH Solutions Pvt Ltd, has launched ProShield ESD 1PP1, a game-changing conductive paint engineered specifically for polypropylene and copolymer substrates. This anti-static coating transforms everyday plastic surfaces into long-lasting ESD-safe zones, ideal for use in electronics manufacturing, automotive, packaging, and more.

It can be applied as a single-part solution for standard environments or as a two-part system (with Hardener 1HD1) for enhanced durability, chemical resistance, and abrasion protection. Its homogeneous conductive matrix ensures consistent electrostatic performance without degradation, even under environmental stress.What sets it apart is its 100% polymer-based formulation, offering uniform resistivity (10⁴–10⁹ ohm/sq) without using carbon powders or metal fillers. It ensures no hotspots, no cracking, and no degradation over time, making it a permanent solution for static control. The ready-to-use paint adheres to almost any surface—metal, plastic, wood, concrete, and even foam—and can be applied with a brush, roller, or spray gun.

Unlike filler-based coatings, it bonds seamlessly with the substrate, retaining the flexibility of polypropylene and adapting to its expansion or movement without cracking or peeling. Once applied, the coating delivers permanent static dissipation or conductivity—as long as the paint remains visible.

Key highlights:

- Surface Resistivity: 10⁴–10⁹ ohm/sq (ASTM D257)

- Coverage: 10–12 m²/kg @ 50 µm

- Finish: Green, smooth, and uniform

- Curing Time: 3 days full cure; tack-free in 45 minutes

- RoHS compliant, low VOC, and free from harmful solvents like toluene, xylene, and MEK

It can be applied using various techniques such as brushing, rolling, dipping, or spraying, provided the surface is properly cleaned and prepared. For standard use, it functions as a single-part system that can be applied directly after stirring and, if needed, adjusting viscosity with Thinner 1ET1. For more demanding environments, the paint can be used as a two-part system by mixing 100 parts of 1PP1 with 6 parts of Hardener 1HD1 by weight. After mixing, the viscosity can again be adjusted with Thinner 1ET1 for ease of application. The mixed two-part formulation should be used within a 45-minute pot life to ensure optimal performance.

Ideal for ESD-sensitive zones, it delivers robust and reliable protection without compromising material flexibility or environmental compliance. This advancement eliminates the need for traditional carbon-filled mats, tapes, or coatings—offering a permanent, maintenance-free alternative for static-safe environments.

For more information, click here.