Printed sensors as small as a micron are moving from lab-scale novelty to real-world deployment, opening new possibilities for robotics, surgery, batteries, and biosensing.

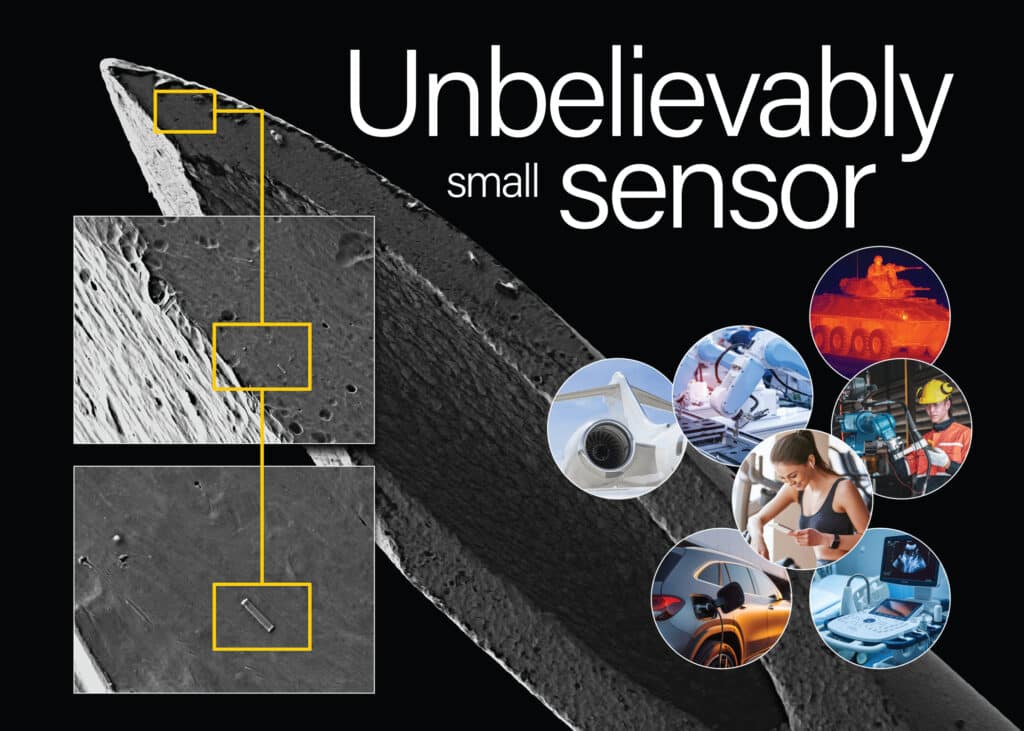

Nanoscale temperature and force sensors small enough to be invisible to the naked eye are now ready for large-scale deployment, marking a significant step toward truly pervasive sensing across machines and medical devices. The sensors by Digid, just 1µm long, can be printed directly onto silicon, metal, polymers, and other substrates, enabling sensing in places where conventional components simply cannot fit.

The move to volume production signals a shift from experimental demonstrations to practical adoption. At this scale, sensors can be embedded on curved, flexible, or confined surfaces without altering mechanical performance, weight, or form factor. This is particularly relevant for emerging fields such as physical AI and humanoid robotics, where machines require dense, distributed sensory feedback to interact safely and precisely with the real world.

The key features are:

- Sensor size as small as 1µm, with roadmap toward 10nm

- Printable on silicon, metal, polymer, and mixed surfaces

- Supports dense sensor arrays for distributed sensing

- Low self-heating with high linearity and accuracy

- Simple I²C output with minimal signal compensation needed

One long-standing challenge in robotics has been the lack of human-like tactile perception. While humans rely on billions of nerve endings to sense pressure and temperature, robot hands typically use a small number of discrete sensors. By contrast, nanoscale printed sensors can be deployed in dense arrays—up to 16 × 16 per surface—allowing machines to detect subtle force and thermal changes across an entire structure, from fingertips to outer shells.

Beyond robotics, the sensors enable new approaches in medical and industrial applications. In robotic surgery, force sensors can be placed directly on scalpel blades to provide real-time tactile feedback, while temperature sensors can be integrated at the tip of minimally invasive probes. In energy systems, sensors embedded inside battery cells can continuously monitor temperature for improved safety and performance. The same platform also supports biosensing, including detection of viruses or chemical markers of drugs in the bloodstream.

Alongside hardware, the solution includes signal processing software that converts raw voltage or resistance data into accurate temperature or force measurements via a standard I²C interface. The approach minimizes digital overhead while delivering stable, linear outputs without the need for complex compensation.With future roadmaps pointing toward sensor dimensions shrinking to the 10nm scale, nanoscale printed sensing is poised to become a foundational technology for next-generation intelligent systems.