The IoT is developing at a rapid pace, and so is the need for small, inexpensive computing hardware. An IoT board must incorporate advanced functionalities in a tiny package.

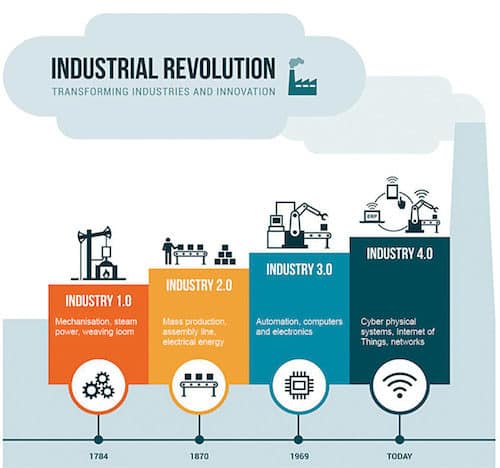

The Internet of Things (IoT) has been described as the fourth industrial revolution by design engineers. It has changed the way we live, by way of smart and self-driving cars, smart cities, drones, intelligent robots, smart grids, the IoT for industrial and agriculture applications, and so much more.

IoT boards incorporate advanced functionalities into a tiny size, which is shrinking forever. In this article, we discuss what an IoT board designer needs to focus on for best results.

Optimising spaces

Every inch of layout space needs to be optimised for all tracks, components and vias. It is about integrating maximum functionality into one board, such as compact size, enhanced data transfer speed, display, sensors, power supply and more, to achieve functionality and flexibility. Every year, we are entering a new design domain that includes high-density interconnect and rigid-flex PCBs. We are living in a market scenario where just good enough PCBs will no longer be accepted. Meeting the needs of this IoT era of flexible electronics requires working with new materials for designs that we can wear on our bodies or even ingest.

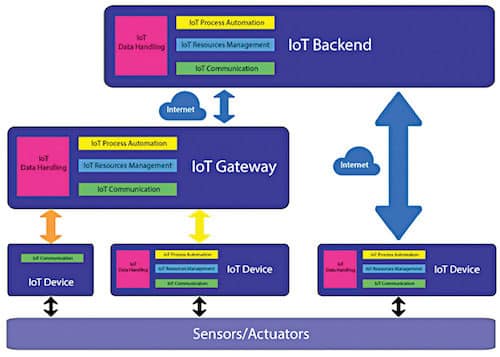

Sunil Deshmukh, senior general manager, technical operation, Millennium Semiconductors, says, “We design smart IoT boards for all segments, including smart homes such as smart lighting, smart switches, wireless controls for home appliances, security systems, energy-saving systems; industrial IoT (IIoT) such as machine control and power-saving systems, data acquisition and management, IoT gateways, production control, industrial safety and RF communications. These boards include sensors, signal conditioning features, smart logics, peripheral controls, wireless communications (Wi-Fi and GSM) and power supplies.”

He adds, “Recently-launched Internet-enabled smart air-coolers can be operated with an app—can control 10 air-coolers at a time. Similar features and functionalities can be applied to other devices or appliances. However, there are challenges with the ecosystem for the development of the IoT. Pricing of product is a challenge. Components have to be imported from China or Taiwan. This creates dependency and limitation for designs.”

New technologies

To keep things slim and thin, designers and manufacturers are collaboratively working on new packaging technologies. They are making the combination of surface-mount and through-hole components technologies redundant. To make integration of digital logic, analogue and RF systems into a single chip seamless, designers are increasingly using system-in-package technique.

Multi-chip module technique helps keep the form factor thin, by connecting multiple ICs on a single die. Three-dimensional IC packaging allows stacking of multiple silicon dies in a single device. This gives a smaller footprint and reduces power consumption.

Designs with efficient power consumption to keep devices working through the day are needed. While planning for power for IoT designs it is important to strategise regarding budget. Power budget should be allocated for each functional circuit block on the PCB. This provides a lot more flexibility than just considering power consumption for the product as a whole.

Wireless connectivity

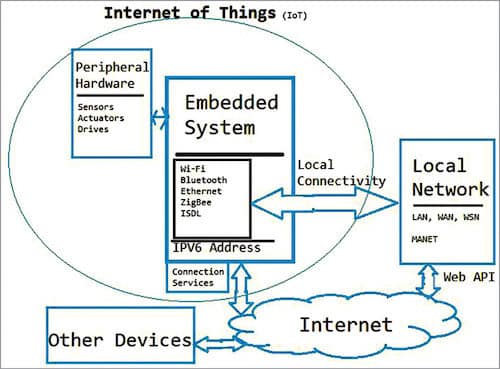

An IoT product may be wired or wireless. It essentially allows a device to sense its surroundings, collect data from multiple sensors and send it to the cloud for interpretation, to present a broader view of the equipment, environment or individual. This is achieved through a variety of wireless, off-the-shelf modules and RF circuits. But, to find room for all of these is a challenge. These parts must have footprints as small as possible while giving all needed functionalities.

Use of wireless modules and protocols in a PCB depends on several factors. These include data transfer speeds, security requirements, required range and power consumption. One or many of these protocols can be used to get the job done—from identification, communication and transport to infrastructure, discovery, data and device management.

There are many other IoT protocols in existence and plenty more in development as the need of our connected future changes. The basic workflow is to build a firewall to protect the IoT devices from unauthorised external access.

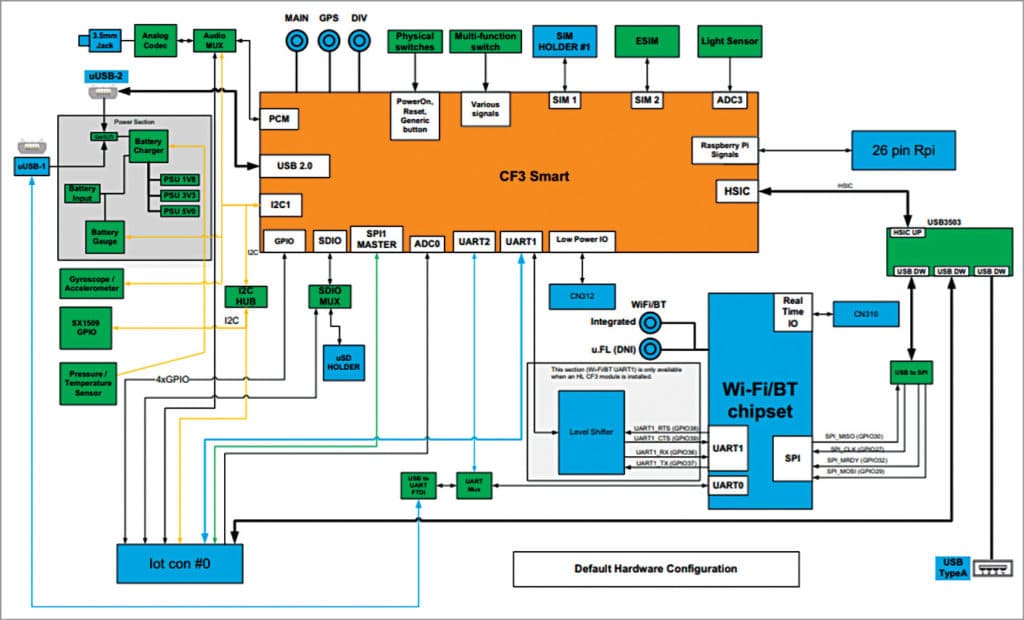

Ashish Syal, chief engineer – IoT, at mangOH, says, “Working with customers, we found that a number of designers often do not try new ideas for the IoT because it is either too expensive or takes too long. We wanted to make it easy for makers and companies to convert their ideas to prototypes, and into products, in the shortest possible time. To do this, we came up with mangOH open hardware platform. It is a highly flexible and expandable open hardware reference design, purpose-built for mobile connectivity. It simplifies the complexity involved in developing new connected mobile products, and removes interoperability issues between mobile and other wired, wireless and sensor technologies.”

He adds, “We are targeting IIoT applications that have seen massive adoption in mobile asset tracking, smart agriculture, smart cities, capital asset monitoring and drones. The boards that we are building are provided under the open source creative commons licence attribution style. This is the most accommodating of licences offered, used for maximum dissemination.”

There are two core elements of project mangOH. First, a series of open platform designs that you can modify and use to build commercial products. You can deploy these reference designs as is, for prototyping. Or you can use these to build your own platform. Basically, the designs cover 80 per cent of the customer use-cases for the IoT.

Second, IoT expansion cards allow adding different combinations of technology. These cards can be used for prototyping and in actual products. Broken wires or connectors causing major issues can be resolved through it.

Syal comments, “Our latest board is mangOH Red. This platform offers many features, including the capability to build low-power IoT applications that can run for 10 years on a battery, snap-in socket to add any compatible modules (2G, 4G, LTE-M/NB-IoT, etc) to achieve up to 10 years of battery life, IoT expansion card slot to plug in any technology based on IoT expansion card open standard, integration with AirVantage IoT platform to create, deploy and manage solutions in the cloud, and built-in Wi-Fi b/g/n and Bluetooth 4.2 BLE with Cortex M4 to provide real-time access to I/O. Next, we are working on massive enablement of next-generation low power wide area (LPWA) applications for LTE-M and NB-IoT.”

Accurate sensor operation relies on careful designing of software and hardware interfaces to meet specific performance requirements. Developers need to carefully consider the placement of the sensor on the board as well as the nature of the housing used to protect sensitive sensors, and optimise sensor accuracy and reliability. For multi-sensor IoT applications, developers need to address issues for each separate sensor to avoid electrical or physical interaction among sensors in the final board design. They need to pay attention at each stage of software and hardware design to achieve reliable humidity and temperature data.

Due to an explosion in the availability of small, inexpensive computing hardware, the IoT is developing at a rapid pace. IoT development boards combine microcontrollers and processors with wireless chips and other components in a pre-built, ready-to-program package. There is sure to be a board that fits your exact requirements, whatever the needs of your product or project.