From smart energy systems to industrial automation, current sensors power precision. They differ in type, function, and application, playing a vital role in today’s connected, electrified world. But how?

A current sensor detects and measures the electric current passing through a conductor. It turns the current into a quantifiable output, such as a voltage, current, or digital signal, which may be utilised in a variety of applications for monitoring, control, or protection. They are also known as current transformers or CTs. They can operate on both alternating current (AC) and direct current (DC) currents.

Current sensors are critical components in a wide range of electrical and electronic systems, ensuring that equipment and gadgets operate safely and efficiently.

In recent years, with the practical application of renewable energy, DC current measurement has also become important, and the demand for the Hall element-based current sensor is increasing.

AC-powered equipment frequently requires critical condition monitoring to ensure operational efficiency and prevent unexpected failures. Banner, a provider of industrial automation solutions, has introduced new Rogowski Coil Current Sensors designed to simplify this task and help maximise machine uptime with ease.

An easy-open flexible loop and compact housing simplifies installation without removing wires or other conductors so that the sensors can be quickly added to existing applications, even in tight spaces. This is just one example depicting the importance of current sensors.

Apart from Rogowski coil, there are several other types. They are:

- Current transformers

- Fluxgate / zero flux

- Open-loop Hall effect

- Closed-loop Hall effect

- Fibre-optic currents sensors

- Shunt resistor

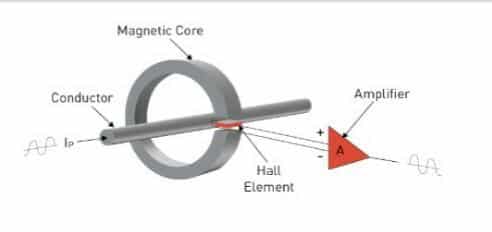

But first, one needs to understand the Hall effect, which generates a voltage perpendicular to the flow of current in a conductor in the presence of a magnetic field. The Hall effect currents sensors utilise this. It refers to the generation of a voltage difference, known as the Hall voltage, in an electrical conductor. This voltage is produced perpendicular to the electric current flowing through the conductor and the applied magnetic field, which is also perpendicular to the current.

Open-loop and closed-loop Hall effect current transducers

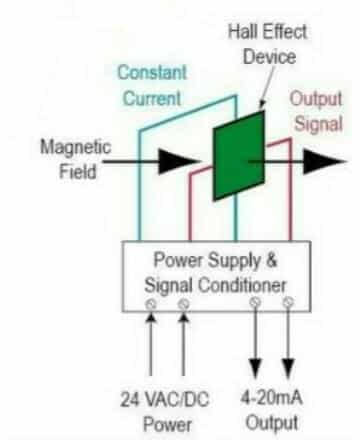

Hall effect current transducers are contactless, providing galvanic isolation between the current source and their output. They are often used in applications where isolation is important.

Both open-loop and closed-loop Hall effect current transducers are available today. Open-loop Hall effect transducers provide an output voltage or current proportional to the strength of the magnetic field. This output is not actively controlled or compensated. Open-loop transducers can be affected by ambient temperature and ageing effects.

These sensors are based on the Hall effect, which states that when a magnetic field is applied across the cross-section of a current carrying conductor, a voltage difference is formed across the conductor (see Fig. 3). We can determine the direction of the electromotive force (emf) that is formed orthogonal to the current and magnetic field using the Fleming left-hand rule. The amplitude and relative angle of the current and magnetic field determine the resultant vector voltage, which is proportional to the Hall constant. The magnetic field is created by the current to be detected, which creates a magnetic field that provides voltage that may be analysed.

Fluxgate current transducers

Fluxgate ‘Zero flux’ current transducers use the principle of magnetic flux modulation to measure electrical currents. They have a magnetic core made of a highly permeable material, such as a nickel-iron alloy.

The magnetic core is typically shaped like a toroid. The primary winding is wound around the magnetic core. The current passing through the primary winding induces a magnetic field in the core.

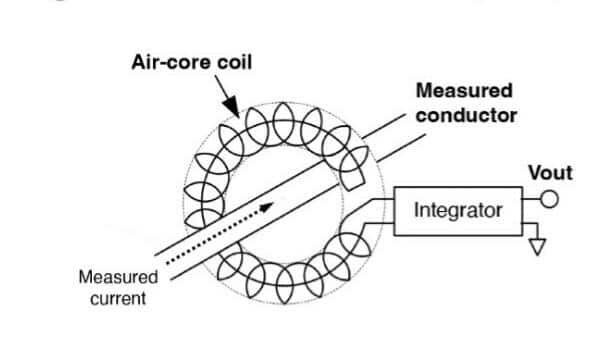

Rogowski coil current sensor

The current sensor using the Rogowski coil method has a flexible and thin design. The air-core coil structure is resistant to magnetic saturation, so linearity is maintained, making it capable of measuring large currents.

Fibre-optic currents sensors

Fiber optic current sensors are resistant to effects from magnetic or electrical field interferences.

Consequently, they are ideal for the measurement of electrical currents and high voltages in electrical power stations.

Fiber optic current sensors are able to replace existing solutions based on the Hall effect, which tend to be bulky and heavy. In fact, those used for high-end currents can weigh as much as 2000kg compared to fiber optic current sensors sensing heads, which weigh less than 15kg.

Fiber optic current sensors have the advantage of simplified installation, increased accuracy and negligible power consumption. The sensing head usually contains a semiconductor light source module, typically an SLED, which is robust, operates in extended temperature ranges. It has verified lifetimes, and is cost-effective.

The advantages of current sensors

- Low heat generation

- Wide measuring range

- An extended bandwidth

- High resolution

- High precision and low offset

- A relatively low measuring error

Although there are limitations…

- They may be affected by Interference from different sources, electromagnetic fields, or sensors.

- Sensors also require ordinary calibration to make certain accuracy.

- They might also have controlled ranges.

Where current sensors are applied?

- Used to detect and monitor currents in power transmission lines, transformers, and circuit breakers

- Fuses and relays are among other protection devices to employ current sensors to prevent equipment damage and assuring safety

- To measure and manage energy usage in residential, commercial, and industrial settings, smart metres, energy monitoring systems, and in demand-side management apps

- In backup power systems like inverters and UPS

- In telecommunication supply units

- In data centres

- Used in motor control systems to monitor and manage the current provided to motors for accurate control of speed, torque, and position

- For monitoring and managing the operation of solar cells, wind turbines, and other renewable energy producing equipment

- To monitor and regulate charging and discharging currents in battery management systems as in electric cars, grid energy storage, and other applications

- Welding machines

- Robot control

The road ahead

Despite some limitations, ongoing advancements in current sensor technology are addressing these challenges and expanding the possibilities for current measurement. As we look ahead, it is clear that current sensors will continue to play a critical role in the development of more sustainable and efficient electrical and electronic systems.

References :

- dewesoft.com

- monolithicpower.com

- hoiki.com

- exalos.com

Authored By: Vinayak Ramachandra Adkoli. The author holds a BE degree in Industrial Production and has been a lecturer in three different polytechnics for ten years. He is also a freelance writer and cartoonist.