The new plastic can fix itself, get back its shape and be reused changing how things are made in defense, aerospace and cars.

A recyclable plastic with self-healing and shape-recovery capabilities could have applications in defense, aerospace, and automotive industries, according to researchers at Texas A&M University. The material, Aromatic Thermosetting Copolyester (ATSP), combines recyclability with mechanical strength, allowing it to withstand stress, high temperatures, and repeated use without losing performance. In aerospace, it could continue operating after damage through on-demand self-healing, while in automotive sectors it could restore vehicle structures after collisions and improve passenger safety.

When reinforced with carbon fibers, ATSP is several times stronger than steel while remaining lighter than aluminum. It can be crushed, remolded, and reshaped through multiple cycles without degrading its core chemistry, making it an alternative to traditional plastics. ATSP belongs to a class of vitrimers that combine the flexibility of thermoplastics with the chemical and structural stability of thermosets. Its self-healing and shape-recovery abilities come from a bond-exchange mechanism: shape recovery allows the material to return to its original form after deformation, while self-healing restores structural integrity after cracks or discontinuities.

Researchers examined ATSP’s properties through cyclical creep testing, repeatedly applying tensile loads to measure how the material accumulated, stored, and released strain energy. They identified two temperatures: the glass transition temperature, where polymer chains gain mobility, and the vitrification temperature, where thermal activation triggers large-scale bond exchanges enabling healing, reshaping, and recovery.

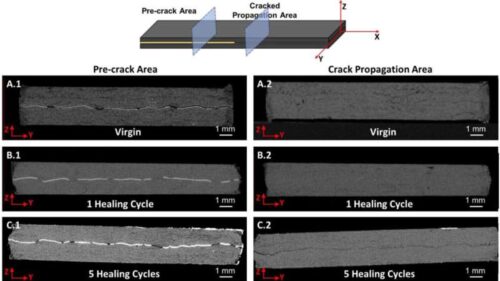

Further experiments used deep-cycle bending fatigue tests, periodically heating samples to around 160°C to activate self-healing. ATSP withstood hundreds of stress and heating cycles without failure and, in some cases, became more durable over time. Additional testing subjected the material to five stress cycles, each followed by heating to 280°C. After two cycles, the composite regained nearly full strength; by the fifth cycle, healing efficiency declined to about 80% due to mechanical fatigue.

High-resolution imaging showed that healed composites closely matched their original structure, with only localized wear linked to manufacturing imperfections. Across all cycles, ATSP maintained its chemical stability and self-healing behavior without signs of thermal degradation. These results indicate that ATSP can adapt to damage, retain performance, and offer a recyclable solution for industries where reliability and sustainability are important.