The design simplifies inverter creation by streamlining component selection, enhancing efficiency, and boosting industry reliability.

The SiC (Silicon Carbide) Power Stack significantly improves the technology used for managing power. It brings several important advantages that are very useful for many industrial uses.

This power stack works more efficiently, can handle more power in a smaller size, and has excellent heat management. It is made to handle the tough requirements of renewable energy, electric vehicle setups, and heavy industry.

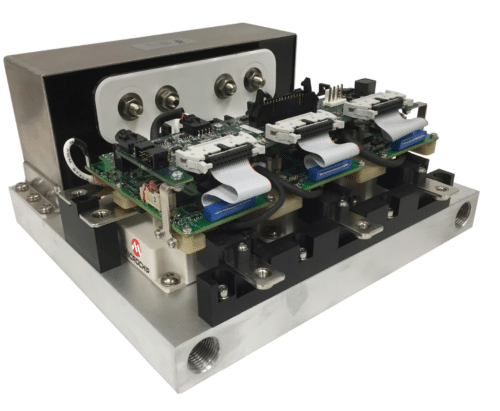

150 kVA 3-phase SiC power stack reference design from Microchip aids inverter designers by streamlining the selection process for individual components. These kits, which are optimally pre-designed for specific applications, can significantly save time and reduce confusion for designers.

Design engineers can use Microchip’s reference design to significantly enhance and streamline their development process in designing high-performance inverters.

The design simplifies the component selection process by offering a pre-designed, optimal configuration that efficiently addresses both typical and complex design requirements.

This saves engineers significant time and reduces the complexities associated with component compatibility and system integration.

The design, which combines power modules, bus bars, cooling systems, gate drivers, and capacitors, streamlines the engineering process by simultaneously tackling electrical, mechanical, and thermal challenges.

Adopting this holistic design strategy ensures the harmonious functioning of all components, optimizing efficiency.

This integrated approach significantly boosts performance and reliability across a wide range of industries, including E-Mobility, DC smart grids, industrial operations, and renewable energy.

The primary users of this service are inverter/stack design houses and R&D labs without their production facilities, as well as OEMs focused on manufacturing stacks and inverters, whether they are niche or broad-market players. System integrators also represent a significant customer segment.

The design offers extensive customization to meet specific client requirements. Options for customization include changing the size and shape of the mechanical frame, adjusting brackets and hardware for better integration, and selecting from various models and types of SiC MOSFET modules, such as a 1700V SiC module.

Clients can choose between air-cooling and liquid-cooling systems and request switching frequency, nominal current, or direct voltage modifications. Additional services include the integration of output filter inductors, testing and qualification services, and the possibility to purchase individual components without assembly.

Featuring high power output in a compact form, the design can operate under high temperatures of up to 130°C and maintains an impressive efficiency rate of nearly 98%.

It incorporates cutting-edge power modules from Microchip and AgileSwitch, supports up to 700 volts and 200 amps, and offers a compact, water-cooled design that allows rapid switching up to 20,000 times per second.

Microchip has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.