This is a small compact ultrasonic sensor for industry 4.0 features low power, real-time data communication for industrial robots.

Engineers often struggle with squeezing complex ultrasonic sensing into tiny spaces like M12 housings while maintaining accuracy and reliability in harsh industrial environments like dust, extreme temperatures, electrical noise, or vibrations that can mess up measurements.

They also need to add smart features like real-time communication with the sensor, ensure low power use for battery-powered devices, and build in protections against power surges or faults without bloating costs or complexity.

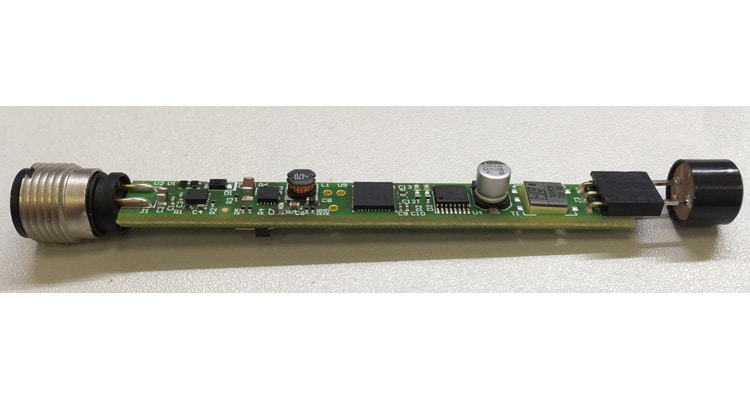

The TIDA-01386 reference design solves these by providing a ready-to-adapt blueprint for the ultrasonic sensor with compact size to fit within an M12 housing with a high integration and an optimised layout. The design includes an Input-Output-Link interface for communication with control systems, making it suitable for Industry 4.0 applications.

These ultrasonics sensors can be used in robots that support in logistics warehouses, industrial robots with programmable functions, can be used as displacement transmitters, level transmitters, and can be used in drones.

Key system specifications include an Input-Output-Link communication interface that comes with the software to analyse the data in real time. The range of this sensor extends from 10 cm to 5m. It uses a frequency of 300KHz for short range of up to 30cm, and a frequency of 58kHz for long range from 30cm to 5m.

This sensor uses the TIOL111 chip for the IO-link communication. It lets the sensor talk to factory machines using IO-Link. It runs on 7-36 volts, protects against electrical shocks or wrong wiring up to 55 volts backward, and can withstand static surges up to 1,000 volts. It’s efficient, using very little power when idle, and sends alerts if something’s wrong, like overheating.

The sensor module contains a piezoelectric transducer that turns electrical pulses into ultrasonic sound and back again, a centre-tap transformer that boosts the drive voltage, and a system-on-chip that houses the analogue front-end, programmable-gain amplifier.

Analogue-to-Digital converter and Digital Signal Processing to drive the transducer and interpret echoes. A low-power microcontroller oversees timing, data processing and protocol tasks, and a transient-voltage suppressor shields everything from electrical surges.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.