The new MIT platform uses multiple materials to fabricate complex electric motors in hours a potential game‑changer for on‑site electronics production.

In a major advance for additive manufacturing and electronics fabrication, researchers at the Massachusetts Institute of Technology have demonstrated a 3D‑printing system capable of producing fully functional complex electric machines including a complete linear motor in just hours using multiple materials.

Traditional manufacturing of electric machines requires separate assembly steps and specialized tooling, often centralized in large factories. This limits on‑demand production of critical components when systems fail, forcing lengthy and expensive supply chains. The new MIT system tackles this by integrating multiple materials including conductive and magnetic substances in a single automated build process.

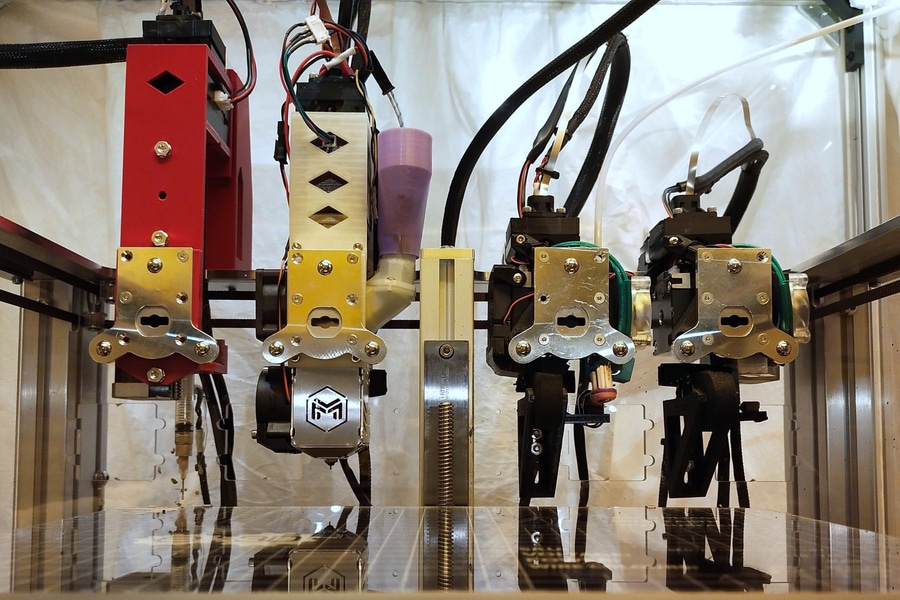

At the heart of the platform is a retrofit 3D printer equipped with four distinct extrusion tools, each able to handle different types of feedstock. The machine swaps between extruders as it prints layer by layer, depositing everything from electrical conductors to hard magnetic material without stopping production. This multi‑material capability is a departure from most extrusion printers that typically handle only two similar‑form materials.

Using this approach, the team printed an electric linear motor, a device that generates straight‑line motion used in robotics and logistics systems, in roughly three hours. After a single post‑print magnetization step, the motor was fully operational, demonstrating performance comparable to or better than conventionally manufactured counterparts, according to the researchers. Material costs for each device were estimated to be around 50 cents.

Beyond just motors, the platform points toward the possibility of on‑site production of customized electronic components for robots, vehicles, and medical devices with significantly less waste. Engineers say integrating the final magnetization step into the printing process and expanding the number of materials could further broaden the system’s capabilities. The advancement underscores a broader trend in additive manufacturing, where advanced printing methods are progressively tackling electronic and functional components not just structural parts potentially reshaping how hardware is prototyped and produced.