The ferrite cores handle more power, work even when hot, and come in many shapes for use in energy, transport, and medical devices.

TDK Corporation has introduced a broad range of new large-size ferrite cores, offering the industry’s widest selection of shapes, sizes, and materials for such cores. These components are engineered for significantly increased power handling, low losses at high switching frequencies, and low losses even at elevated temperatures ranging from +100 °C to +140 °C. Designed for use across various industrial applications, these cores support optimized magnetic performance and improved thermal efficiency in systems such as motor drives, EV charging stations, railway and traction systems, power transformers, welding equipment, medical devices, uninterruptible power supplies (UPS), solar inverters, and other renewable energy technologies.

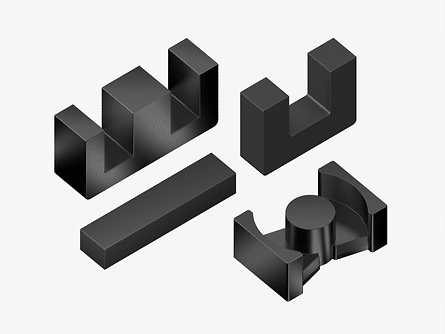

The newly standardized lineup includes popular core shapes such as E, U, I, PM, and PQ, and is available in power materials including N27, N87, N88, N92, N95, and N97. TDK also provides essential accessories like coil formers—including versions designed for multiple stacked E-cores—and mounting hardware to simplify integration into power systems.

To support the design process, TDK offers the Ferrite Magnetic Design Tool free of charge, helping engineers simulate and optimize magnetic designs for improved efficiency and thermal behavior.

In traction and railway systems, these ferrite cores play a key role in managing high power levels and ensuring efficient energy conversion in challenging conditions. For electric vehicle (EV) and battery charging infrastructure, the cores deliver stable power transfer and thermal stability under high-load scenarios.

In renewable energy applications—including wind and solar—they contribute to the reliable and efficient operation of power inverters and related systems. Energy storage systems benefit from the cores’ ability to handle power flows efficiently during both charging and discharging cycles.

In welding systems, the cores maintain stable power output and help reduce energy losses during high-frequency operations. In the medical sector, they are used in various high-frequency and power supply devices where performance and reliability are critical.