The fiber does electronic work and then breaks down in soil. It may help reduce waste from clothes and other wearable devices.

Researchers at Seoul National University have developed a type of fiber that works like electronic materials but breaks down after use. It functions during its life and then degrades in soil or enzyme-rich environments, leaving no waste. The goal is to reduce the problem of electronic textile waste.

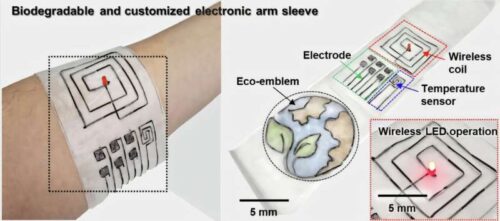

The team tested this fiber by building a sleeve. The sleeve included a temperature sensor, EMG electrodes, and a wireless power coil. It worked during movement and under different environmental conditions. Once no longer used, the sleeve—including an embroidered symbol—began to break down and decomposed in a few months.

The fiber shows performance with electrical conductivity around 2,500 S/m. It can stretch up to 38% without breaking, withstand over 20 wash cycles, and survive more than 5,000 bends. These features match or exceed many current e-textile materials. The fiber is also compatible with dry-jet wet-spinning, a process that allowed the team to produce over 10 meters in one run.

The fiber is made by combining tungsten microparticles with a polymer called PBAT (poly(butylene adipate-co-terephthalate)), creating a conductive core. It is then coated with an outer layer made from polyanhydride (PBTPA), which provides strength while still allowing the fiber to break down.

This development offers a possible way to deal with waste from wearable devices. Matching a device’s life with its use can lead to new options in patches, uniforms, sensors, and healthcare systems.

The research brings together biodegradability, strength, and manufacturing. Future work will focus on adding memory and logic to support more devices. The team is also exploring “triggerable” degradation—designing materials that break down in response to signals like light, heat, or pH, allowing for lifespans based on use.

Each year, the world generates over 92 million tons of textile waste, much of it from materials that do not break down. With more use of wearable electronics—such as watches, bands, and clothing with sensors—the problem becomes more complex. E-textiles often contain metal wires, plastic layers, adhesives, and circuits, making them hard to recycle.

This research shows it is possible to build wearable devices that can also return to the environment after use.